Packaging equipment

Libra Vitalis » Products » Equipment » Packaging equipment

Strapping Machines

- Fast and convenient bundling and securing of products.

- Aesthetic packaging – clean, tidy, and free of adhesive residues.

- Compatible with paper or film straps.

- Straps can be customized – plain or printed.

- Saves materials and reduces packaging waste.

- Compact desktop models for small print runs.

- Semi-automatic systems with quick changeover.

- Fully automatic models integrated into production lines.

- Solutions with built-in printers for labelling.

- Ultrasonic welding – quiet, fast, and economical.

- Impulse heat sealing – reliable and versatile.

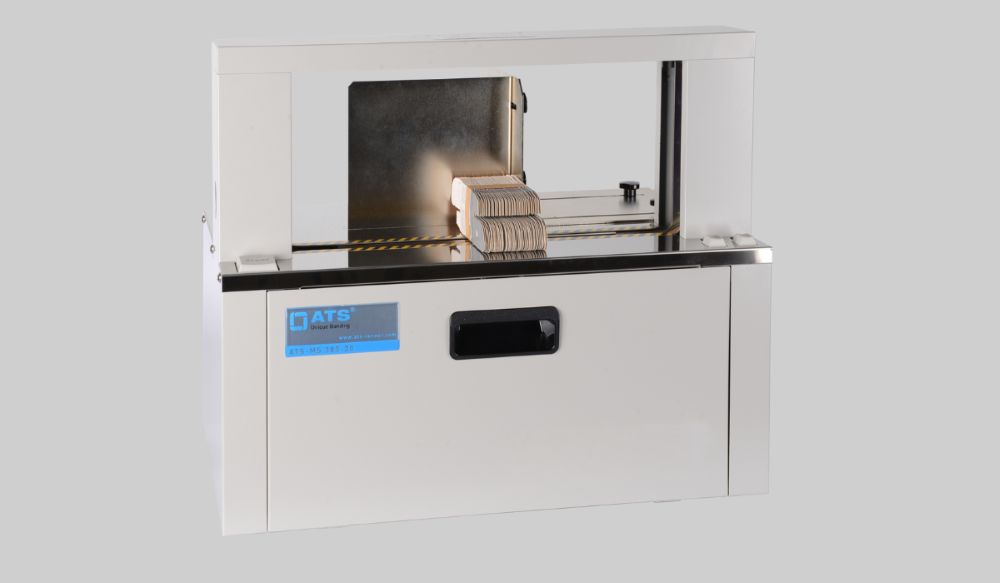

ATS-MS 380 20 mm

ATS-MS 380 20 mm – compact, mobile, and easy-to-use tabletop Heat-Seal strapping machine designed for 20 mm wide paper or film straps. This model is ideal for bundling small products, especially in the printing and logistics sectors.

- Impulse heat sealing: Operates instantly without warm-up, safe and reliable.

- Non-slip design: Easily movable and usable in various workstations.

- Tension adjustment: Direct strap tension control.

- Flexible feeding: Manual, foot pedal, or automatic cycle start.

- Optional jumbo roll holder: Reduces strap changes and improves productivity.

- Printing, publishing, and packaging sectors: For quick product bundling or label securing.

- Small product bundling: Suitable for items up to 380 × 160 mm.

- Logistics and fulfillment centers: Safe and neat labeling without plastic wrap.

- Strap width: 20 mm

- Max product size (W × H): 380 × 160 mm

- Min product size (W × H): 20 × 1 mm

- Speed: Up to 28 straps/min

- Dimensions: ~520 × 300 mm (W × D)

- Table height: ~240–440 mm

- Weight: ~35 kg

- Power: ~0.2 kW, 230 V (single-phase)

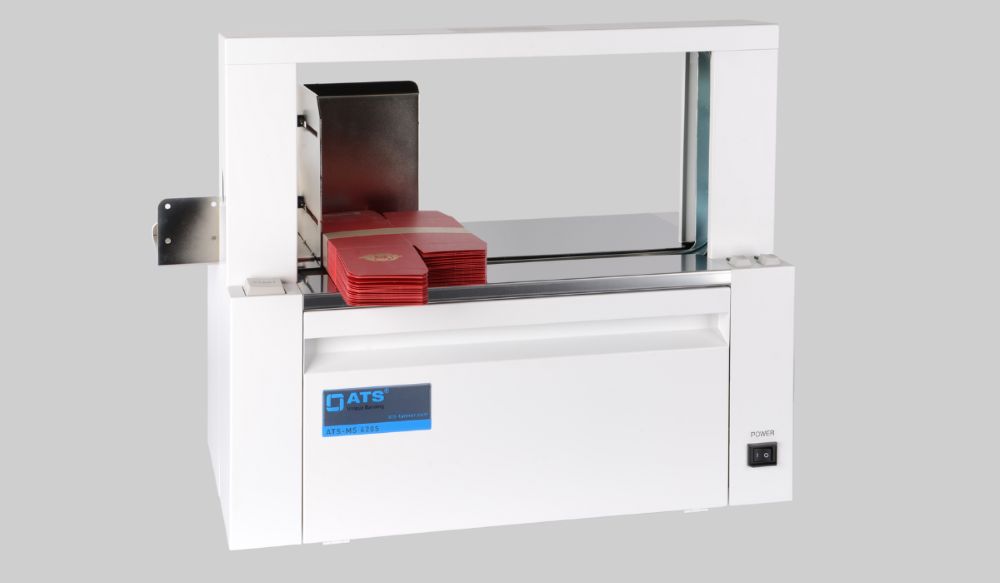

ATS-MS 420S 30 mm

ATS-MS 420S – compact strapping machine designed for 30 mm wide paper or film straps. Using impulse heat sealing technology, it ensures precise, clean, and fast strapping without warm-up time. Ideal for small to medium-sized products where safety and aesthetic appearance are important.

- Impulse heat sealing: Cycle starts instantly, ensuring fast and safe operation.

- 30 mm strap compatibility: Works with both paper and film straps.

- Fixed arch: Pre-formed strap loop allows easy product placement.

- Adjustable tension: Strap tension can be set according to product fragility or required firmness.

- Flexible operation: Manual, foot pedal, or automatic cycle start.

- Optional jumbo roll holder: Reduces interruptions from strap roll changes.

- Printing and publishing – bundling brochures, catalogs, labels, or publications.

- Packaging and logistics – quick grouping and labeling of small products.

- Securing small products – ensures stability without damaging product appearance or structure.

- Strap width: 30 mm

- Max product size (W × H): 420 × 200 mm

- Min product size (W × H): 20 × 1 mm

- Speed: Up to 26 straps/min

- Strap tension range: 5–20 N

- Power supply: 230 V, single-phase

- Power consumption: ~0.2 kW

- Dimensions (W × D × H): ~560 × 330 × 470 mm

- Weight: ~40 kg

ATS-MSXII 420 30 mm

ATS-MSXII 420 – high-end strapping machine designed for fast and precise bundling of products using 30 mm paper or film straps. This new-generation Heat-Seal model offers higher performance, stronger tension, and greater flexibility, ideal for companies prioritizing quality, speed, and aesthetic finishing.

- Impulse heat sealing: Ready for use immediately after power-on, no warm-up required.

- 30 mm strap compatibility: Supports both paper and film straps.

- Fixed arch: Ensures precise strap feeding and easy product placement.

- Automatic preparation: No additional setup or preheating needed.

- Increased strap tension range: From light to very strong (5–60 N), suitable for various products.

- Faster cycle: Up to 33 straps per minute for higher productivity.

- Ergonomic design: Safe work area, rounded corners, compact footprint.

- Printing, publishing, and packaging – bundling brochures, catalogs, labels, or cards.

- Logistics and warehousing – fast grouping and labeling of small products.

- Food, pharmaceutical, and cosmetics industries – ensures clean, strong, yet easily removable strapping.

- Strap width: 30 mm

- Max product size (W × H): 420 × 210 mm

- Min product size (W × H): 20 × 1 mm

- Strapping speed: Up to 33 cycles/min

- Strap tension: Adjustable 5–60 N

- Power supply: 230 V, single-phase

- Power consumption: ~0.2 kW

- Dimensions (W × D × H): ~560 × 330 × 490 mm

- Weight: ~40 kg

ATS US-3000 AD

ATS-US 3000 AD – advanced semi-automatic strapping machine using ultrasonic welding technology.

- Ultrasonic welding: Heat-free, safe for sensitive surfaces, no preheating required, highly energy-efficient (~98% less than thermal sealing machines).

- Immediate start-up: Ready to use as soon as the machine is powered on.

- User-friendly interface: Touchscreen interface, intuitive operation, suitable for any language user.

- High ergonomics: Adjustable-height table, convenient strap holder, easily replaceable rolls.

- Advanced diagnostics: Built-in sensors (temperature, humidity, vibration, noise) with IO-Link data transfer for preventive maintenance.

- Ideal for bundling food, cosmetics, pharmaceuticals, textiles, and printed products.

- Suitable for both stationary lines and mobile setups in wet, dusty, or cold environments.

- Efficient, safe, and sustainable alternative for companies aiming to reduce plastic use and improve packaging aesthetics.

- Strap width: 30 mm

- Strap type: Paper or film (adhesive-free)

- Max product size (W × H): 360 × 200 mm

- Min product size (W × H): 30 × 10 mm

- Strap tension: Adjustable (no mechanical pulling system)

- Performance: Up to 38 straps/min

- Welding technology: Ultrasonic (heat-free, smoke-free, odorless)

- Start modes: Automatic, foot pedal, or manual

- Display: Color touchscreen

- Integration: IO-Link, USB, Ethernet

- Power supply: 230 V, 50–60 Hz, single-phase

- Power consumption: ~0.2 kW

- Dimensions (W × D × H): ~650 × 670 × 1120 mm

- Weight: ~115 kg

ATS US-2500 AD-A

ATS-US 2500 AD-A – semi-automatic strapping machine using ultrasonic welding technology, designed for fast integration into automated production lines. This model offers high reliability, efficient strap changes, and stable operation in demanding manufacturing environments.

- Ultrasonic welding (heat-free): No added heat, odorless, smoke-free, safe joint.

- Modern modular design: Quickly adaptable to automated lines, supports fast strap changes and minimal downtime.

- Strap compatibility: Works with paper and film straps, typically 30 mm or 50 mm wide.

- Intuitive operation: Simple user interface, quick settings, and diagnostic functions.

- Suitable for food, textiles, pharmaceuticals, and printed products requiring efficient, aesthetic bundling and labeling.

- Ideal for logistics, just-in-time packaging, and color identification processes.

- Perfect solution for companies seeking eco-friendly, sustainable, and energy-efficient strapping solutions.

- Strap width: 30 mm (50 mm versions available)

- Performance: Up to 38 straps per minute

- Welding technology: Ultrasonic (no cooling required)

- Start modes: Automatic, manual, or foot pedal

- Diagnostics: Built-in signals and service indicators (temperature, vibration, humidity)

- Integration interfaces: IO-Link, Ethernet, USB

- Power supply: 230 V, 50–60 Hz

- Power consumption: ~0.2 kW

- Weight: Medium-range standard configuration

- Dimensions: Compact, line-integrable design

ATS US-2500 TTP

ATS-US 2500 TTP – modern strapping machine with ultrasonic (heat-free) welding, integrated thermal transfer printer, and automated strap preparation system. This model combines two operations – strapping and labeling – into a single efficient process, making it ideal for companies looking to simplify packaging and data printing workflows.

- Ultrasonic welding: Precise, strong joints without heat or smoke, safe for sensitive materials.

- Integrated thermal transfer printer: Prints product information (price, weight, expiry date, batch number, 1D/2D codes) directly on the strap during strapping.

- “Print mark” sensors: Automatic positioning on pre-printed or blank straps.

- Universal strap compatibility: Supports 30 mm paper or film straps (50 mm versions available).

- V6 control unit ready for IIoT: Supports Ethernet, USB, and IO-Link interfaces.

- Food, cosmetics, textiles, logistics – combining labeling and strapping in one operation.

- Just-in-time labeling solutions – one machine prints and straps for fast production lines.

- E-commerce and fulfillment centers – strapping and identification without additional film.

- Strap width: 30 mm (50 mm versions possible)

- Performance: 30–38 straps per minute (depending on product size and arch format)

- Welding technology: Ultrasonic, cold-type (heat-free)

- Printing: Thermal transfer, up to 4 prints per strap fragment

- Start modes: Automatic, foot pedal, or manual

- Integration interfaces: IO-Link, Ethernet, USB

- Power supply: 230 V, single-phase

- Power consumption: ~0.2 kW

- Machine dimensions: Compact, line-integrable (~650 × 670 × 1120 mm)

- Weight: ~100–120 kg (line version)

Shrink Wrapping Equipment

- Reliable product protection against moisture, dust, and mechanical damage.

- Aesthetic and commercially appealing packaging appearance.

- Reduced use of excess packaging material.

- Suitable for both individual products and product bundles.

- Compact manual solutions for small volumes.

- Semi-automatic machines for medium volumes.

- Automatic systems for high-volume production lines.

- Food industry

- Cosmetics and perfumery

- Printed materials and publications

- Pharmaceutical industry

- Electronics and household appliances

Smipack SL45

SMIPACK SL45 – a compact, semi-automatic L-seal packaging machine designed for packing products in shrink film. This model is intended for small to medium production volumes, ensuring professional results, user-friendly operation, and cost-effective performance.

- Single-cycle operation: Sealing and shrinking of the film occur simultaneously, providing fast and smooth packaging.

- PTFE-coated sealing blade: Prevents film from sticking, extends service life, and ensures a clean cut.

- Electronic control panel: Allows saving up to 6 programs with different temperature, time, and cycle settings.

- Automatic lid lift: The lid raises automatically after the shrinking cycle, facilitating workflow.

- Adjustable packaging platform: Adapts to products of varying heights for high-quality results.

- Air-cooled housing: Ensures longer service life and stable operating temperature.

- Food and beverages: Packaging of confectionery, baked goods, snacks, and other products.

- Cosmetics and household chemicals: Professional packaging with visual protection.

- Printing and publishing: Packaging of books, catalogs, or other printed materials before delivery or sale.

- Other sectors: Electronics, textiles, toys, pharmaceuticals, and household goods.

- Sealing area: 440 × 300 mm

- Maximum package height: 210 mm

- Film type: PVC or polyolefin (POF), up to 30 μ thick

- Maximum roll diameter: Ø 250 mm

- Power: 1650 W

- Voltage: 230 V, single-phase, 50/60 Hz

- Capacity: Up to 300 packages per hour (depending on product and operator speed)

- Dimensions (with stand): approx. 1070 × 665 × 1015 mm

- Machine weight: approx. 60 kg + stand weight (~11–15 kg)

Smipack SL55

SMIPACK SL55 – a semi-automatic L-seal packaging machine designed for shrink film applications. This upgraded model offers higher performance and a larger sealing area, making it suitable for small to medium production volumes seeking professional-quality packaging.

- Single-cycle operation: Sealing and shrinking are performed in one smooth motion, enabling fast packaging.

- PTFE-coated sealing blade: Reduces film sticking, improves seal quality, and extends service life.

- LCD control panel: Allows saving up to 6 temperature and time profiles for quick adjustments.

- Automatic lid opening: Enhances safety and workflow efficiency.

- Air-cooled construction: Ensures stability and durability even under intensive use.

- Ideal for small to medium production volumes in food, cosmetics, electronics, printed materials, household goods, and similar packaging needs.

- Works with PVC or POF films (up to 30 µ) for strong, aesthetically pleasing packages.

- Suitable for environments producing up to 300 packages per hour without large-scale production lines.

- Sealing area: 560 × 430 mm

- Maximum package height: 260 mm

- Maximum film roll size: 600 × Ø 250 mm

- Capacity: Up to 300 packages per hour

- Voltage: 220–240 V, single-phase, 50/60 Hz

- Power: 3,700 W

- Dimensions (with stand): approx. 1260 × 805 × 1100 mm

- Machine weight: approx. 77 kg (without stand); with stand ~88 kg; with wheels ~95 kg

Smipack S560

SMIPACK S560 – a semi-automatic shrink film packaging machine with an integrated L-seal system. It is ideal for companies seeking a faster and more precise packaging process.

- Integrated sealing and shrinking cycle: Both operations are completed in a single step, ensuring fast and efficient packaging.

- Electronic control via LCD panel: Allows storing up to 6 packaging programs with precise adjustment of temperature and cycle time.

- Electromagnetic lid: Automatically lifts at the end of the cycle, ensuring convenience and consistency.

- Air-cooled chamber: Maintains optimal operating temperature even during prolonged use.

- High-quality components: Sealing blade coated with PTFE for long-lasting operation without sticking or wear.

- Suitable for small and medium-sized companies requiring professional-looking, reliable, and efficient packaging.

- Ideal for packaging food products, cosmetics, pharmaceuticals, printed materials, toys, electronics, and textiles.

- Compatible with PVC and POF shrink films up to 30 µ thick.

- Sealing area: 560 × 430 mm

- Maximum package height: 260 mm

- Maximum film roll size: 600 mm width, Ø 250 mm

- Capacity: Up to 900 packages per hour (depending on product and operator speed)

- Voltage: 220–240 V, single-phase, 50/60 Hz

- Power: 3,700 W

- Dimensions (with stand): approx. 1260 × 805 × 1100 mm

- Weight: approx. 77 kg (without stand)

Smipack FP560A

SMIPACK FP560A – an automatic L-seal type shrink film packaging machine, designed for efficient and professional packaging in various industries.

- Automatic operation: The machine controls the sealing cycle and lid opening/closing automatically, increasing productivity.

- Large working area: Allows packaging of larger products while maintaining high quality and aesthetics.

- Integrated control unit with LCD screen: 6 programmable profiles for quick switching between different products.

- Durable components: PTFE-coated sealing blade, air-cooled system, CE certified.

- Versatility: Compatible with PVC and POF shrink films up to 30 µ thick.

- Ideal for companies performing continuous packaging in food, cosmetics, printing, toys, electronics, or pharmaceutical industries.

- Ensures reliable protection for transport and visually appealing presentation for retail.

- Suitable for both individual products and grouped packaging.

- Sealing area: 560 × 430 mm

- Maximum package height: 230 mm

- Maximum film roll size: 600 mm width, Ø 250 mm

- Capacity: Up to 900 packages per hour

- Voltage: 220–240 V, single-phase, 50/60 Hz

- Power: 3,700 W

- Dimensions: approx. 1260 × 805 × 1480 mm

- Weight: approx. 140 kg

Smipack FP6000

SMIPACK FP6000 – a fully automatic L-seal shrink film packaging machine designed for high-output production. This model is engineered for continuous operation with a variety of products, offering high packaging speed, precision, and user-friendly control. It is a reliable solution for companies that require efficient, high-quality, and visually appealing packaging.

- Fully automatic operation: The cycle runs without operator intervention – products are fed, wrapped, and sealed automatically.

- Integrated conveyor system: Continuous product feeding maximizes machine throughput.

- Electronic control with LCD screen: Up to 20 programmable packaging programs for quick product switching.

- High-quality sealing system: PTFE-coated sealing blade allows use with various film types.

- Versatility: Compatible with PVC and POF shrink films up to 30 µ thick.

- Ideal for companies with continuous production processes in food, cosmetics, pharmaceuticals, household goods, publishing, printing, or electronics industries.

- Suitable for packaging individual items or grouped products in various package sizes.

- Ensures attractive presentation for retail and reliable protection for storage or transport.

- Sealing area: 640 × 510 mm

- Maximum package height: 240 mm

- Maximum film roll size: 700 mm width, Ø 300 mm

- Capacity: Up to 3,000 packages per hour (depending on product and configuration)

- Voltage: 220–240 V, single-phase, 50/60 Hz

- Power: 4,200 W

- Dimensions: approx. 2010 × 790 × 1505 mm

- Weight: approx. 310 kg

Smipack HS700

SMIPACK HS700 – a high-performance, fully automatic L-seal shrink film packaging machine designed for continuous industrial production. This model is engineered for maximum speed, precision, and efficiency, even with larger or more complex products. It represents one of Smipack’s most advanced solutions for automated shrink film packaging.

- Fully automatic operation: Products are fed, wrapped, sealed, and prepared for shrinkage without operator intervention.

- Designed for intensive use: Suitable for continuous production while maintaining speed and accuracy.

- Electronic control with expanded program capacity: Up to 20 programmable packaging profiles can be saved on the control panel.

- Conveyor system with adjustable speed: Ensures smooth product flow even at high volumes.

- Advanced sealing system: PTFE-coated sealing blade, resistant to wear and temperature fluctuations.

- Ideal for companies requiring very high-speed packaging and automation – suitable for food, cosmetics, printing, pharmaceuticals, textiles, electronics, and household goods industries.

- Suitable for packaging products of various sizes, shapes, and grouped items in PVC or polyolefin (POF) shrink film.

- Easily integrated into automated production lines with tunnels, sorting systems, or robotics.

- Sealing area: 700 × 570 mm

- Maximum package height: 300 mm

- Maximum film roll size: 700 mm width, Ø 300 mm

- Capacity: Up to 4,200 packages per hour (depending on product and configuration)

- Voltage: 220–240 V, single-phase, 50/60 Hz

- Power: 4,500 W

- Dimensions: approx. 2345 × 1370 × 1505 mm

- Weight: approx. 405 kg