Post-press equipment

Libra Vitalis » Products » Equipment » Post-press equipment » Post-press equipment: book finishing, folders

BOOK Finishing

- Mitabook, Mitacase, Mitatrim – flexible solutions for digital print runs;

- Efficient binding, cover formation, and trimming.

- Proxima, Trimming, Universe, Universe Web – sewn books from sheets or rolls;

- Hunkeler PF7 – roll-fed folding for further processing.

Digibook Mitacase

Mitacase – a digital, fully automatic hardcover production system. Its standout feature is that no mechanical adjustments are required when changing job parameters – all settings are configured directly via the control panel.

Key Advantages:

- Fully automatic operation

- Parameter changes without mechanical intervention – all adjustments via touchscreen

- Designed for professional digital hardcover production

Technical Specifications:

- Speed: up to 7 units/min

- Minimum cover size: 223 × 125 mm

- Maximum cover size: 800 × 420 mm

- Dimensions: 2950 × 2670 × 1650 mm

- Weight: 2900 kg

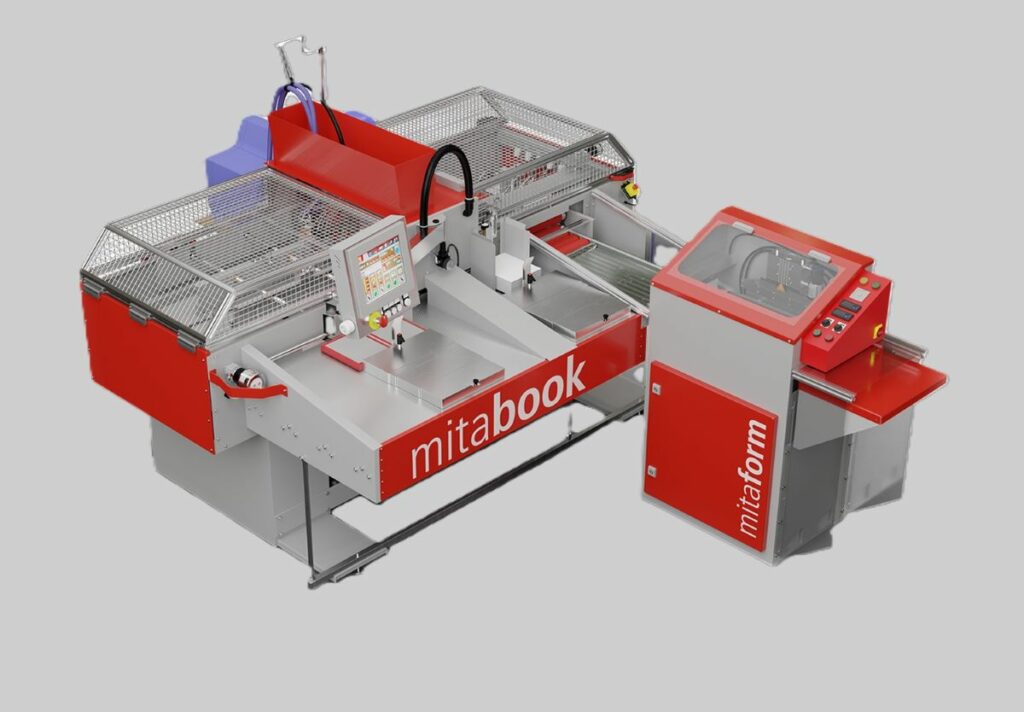

Digibook Mitabook

Mitabook – a compact digital automatic system designed for gluing book blocks into hardcover cases. Ideal for small-run book production, ensuring precise and aesthetically pleasing results.

Key Advantages:

- Compact and convenient for small spaces

- Fully automatic operation with precise block gluing

- Especially suitable for small-run book production

Technical Specifications:

- Speed: up to 7 books/min

- Minimum block dimensions: 145 × 125 × 2 mm

- Maximum block dimensions: 350 × 410 × 40 mm

Digibook Mitatrim

Digital Automatic Three-Knife Cutter – can operate both in inline and offline mode. The device supports barcode use, enabling automated workflows – format changes are carried out automatically according to pre-set cutting parameters.

Key Advantages:

- Operates both in inline and offline mode

- Automatic format changes via barcode recognition

- Extremely precise and efficient three-edge cutting

Technical Specifications:

- Speed: up to 800 cycles/hour

- Block/book width: 110 – 330 mm

- Block/book height: 160 – 360 mm

- Block/book thickness: 3 – 60 mm

Meccanotecnica Proxima

Meccanotecnica Proxima – a high-end automatic system for softcover book production after the sewing process. The device combines spine pressing, gluing, cover application, and alignment in a single workflow. Ideal for print shops seeking efficiency and high-quality results.

Key Advantages:

- Fully automated process – from block insertion to finished book

- 4-ton press – ensures precise spine compression and squaring

- Accurate cover gluing – for durability and aesthetics

- Integrated alignment module – professional cover presentation

- Can be integrated into sewing and trimming lines

Technical Specifications:

- Speed: up to 30 books/min

- Book format: max. 320 × 440 mm

- Book thickness: 2–80 mm

- Pressing force: 4 tons

- Operation: automated, single-operator control

Meccanotecnica Trimming

Trimming – automatic three-knife trimmer designed for trimming blocks and softcover books. When changing product sizes, no mechanical adjustments are needed – knife positions are adjusted automatically via the control panel. The cutting process occurs in two stages: first the top and bottom are cut, then the front. The device recognizes different formats via barcode and adapts automatically. Suitable for hardcover dust jackets and supports both offline and inline operation.

Key Advantages:

- Automatic repositioning based on barcode

- Operation without mechanical adjustments – all settings via control panel

- Can handle multiple formats simultaneously

- Suitable for softcover books with dust jackets

- Operation modes: offline and inline

Technical Specifications:

- Output (single format): up to 2400 units/hour

- Output (multiple formats): up to 1200 units/hour

- Maximum book size: 480 × 320 × 60 mm

- Minimum book size: 140 × 93 × 3 mm

- Maximum trimmed size: 420 × 300 × 60 mm

- Minimum trimmed size: 130 × 90 × 3 mm

- Maximum cutting distance: 25 mm

- Minimum cutting distance: 3 mm

- Weight: 1400 kg

Meccanotecnica Universe

Universe Sewing – a next-generation universal book block sewing machine, suitable for both offset and digital print. The machine features an integrated registration system for precise sheet stacking and sewing preparation. Using a barcode reader, blocks of different thicknesses can be processed simultaneously, and all settings are managed via a PC panel – no mechanical adjustments required.

Key Advantages:

- Automatic adjustment of working parameters via the control panel

- Integrated sheet registration for precise sewing

- Barcode reader allows processing of blocks of different thicknesses simultaneously

- Hybrid feeding – compatible with both offset and digital print at the same time

- High performance – up to 550 A4 sheets per minute

Technical Specifications:

- Minimum paper size: 150 × 200 mm

- Maximum paper size: 420 × 640 mm

- Minimum booklet size: 150 × 100 mm

- Maximum booklet size: 420 × 320 mm

- Maximum booklet thickness: 1.5 mm (single), 3 mm (folded)

- Number of needles: up to 10

- Paper weight: 40–220 gsm

- Feed table stacking height: up to 500 mm

- Mechanical speed: up to 167 cycles/min

- Paper feed speed: up to 550 sheets/min

- Air pressure: 7 bar

- Power: 4.5 kW

- Weight: 3050 kg

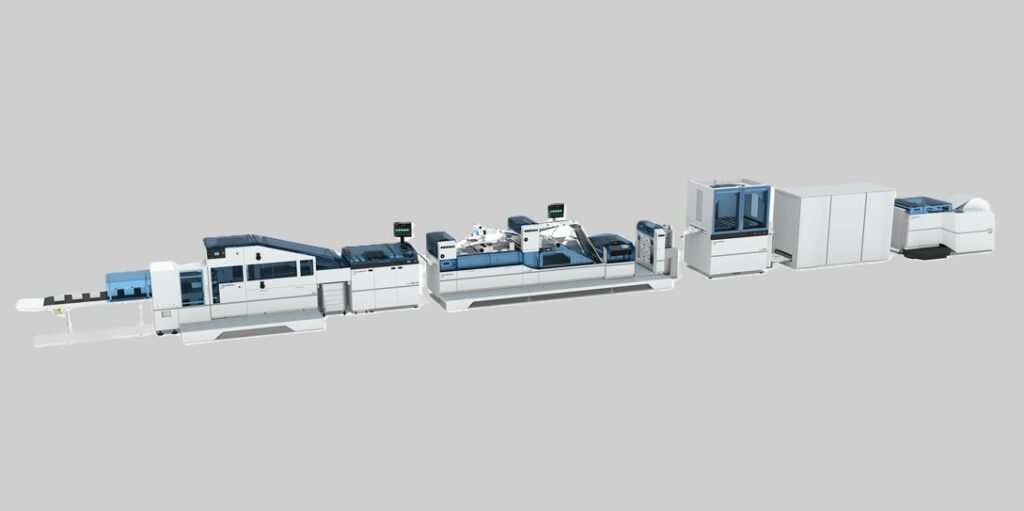

Meccanotecnica Universe Web

Meccanotecnica Universe Web – an innovative, fully automated book sewing system designed for direct roll-to-roll operation. The machine handles the entire process – from unwinding the paper roll to producing a sewn book block – without requiring any intermediate steps. It is ideal for high-volume print shops looking to optimize production efficiency.

Key Advantages:

- Fully automated process – from roll to sewn book block

- Integrated signature forming and sewing module – ensures quality and precision

- High production speed – efficient solution for large print runs

- Can be integrated with other machines, e.g., Proxima or Trimming

- Suitable for both color and monochrome print

Technical Specifications:

- Maximum speed: up to 4,000 signatures/hour

- Sewing module: automatic, multi-needle

- Signature format: flexible, customizable per job

- Output: automatic book block formation

CreoBook Lay-flat

CreoBook Three Knife Trimmer

Hunkeler Plowfolder PF7

Hunkeler Plowfolder PF7 – a high-performance automatic folder designed to form signatures from individual sheets directly from a roll. Ideal for print production lines that require fast and precise preparation of book blocks for sewing or further processing.

Key Advantages:

- Works directly from the roll – continuous and cost-efficient signature formation

- Precise plow folding – clean and accurate folds

- Flexible folding – supports single or multiple sheets per signature

- Easily integrates with other Hunkeler solutions – full automation

Technical Specifications:

- Paper source: roll

- Maximum speed: up to 200 m/min

- Paper width: up to 762 mm

- Folding: up to 6 folds per signature

- Compatibility: integrates with sewing, trimming, and gluing modules

Folders

- Automated operation – quick setup for immediate use;

- Capability to handle products of various formats and paper types;

- Compact models for office use and professional solutions for production;

- Easy control via LCD screen or touch panel.

- Simple single fold;

- Z-fold;

- C-fold;

- Double parallel fold.

DUPLO DF-999

Duplo DF-999 – an exceptionally fast and quiet folder, designed to save time and reduce production costs. The device allows storing up to 30 different job settings, and its adjustable speed ensures consistent accuracy. Suitable for folding non-standard formats, it features double-sheet detection, interval mode, and numerous other functions for unrestricted print finishing.

Key Advantages:

- Fast and quiet operation – efficient folding process

- Up to 30 saved job formats and parameters

- Adjustable speed – ensures accuracy and stability

- Capability to fold non-standard paper formats

- Double-sheet detection and interval mode

- Various standard fold types: half, double parallel, letter, Z, half Z, open gate

Technical Specifications:

- Minimum paper size: 74 × 105 mm

- Maximum paper size: 311 × 457 mm

- Speed: up to 260 sheets/min

- Paper weight: 47–157 g/m²

- Maximum stack height: 46 mm

- Feeding type: friction

DUPLO DF-1300L

Duplo DF1300L – a fast and quiet folder with an integrated vacuum belt feeding system. The device allows storing up to 30 different job formats and parameters. Its adjustable operating speed ensures consistent accuracy and process stability even during high-volume work.

Key Advantages:

- Integrated vacuum belt feeding system – precise and gentle paper handling

- Up to 30 saved job parameters – quick job changeover

- Adjustable speed – consistent results regardless of print volume

- Suitable for various paper sizes and weights

- Quiet operation – ideal for offices or small production areas

Technical Specifications:

- Minimum paper size: 120 × 182 mm

- Maximum paper size: 310 × 648 mm

- Paper weight: 52–230 g/m²

- Speed: up to 310 sheets/min

- Maximum stack height: 50 mm

Offset folders

Libra Vitalis will configure and provide the optimal offset folders setup tailored to your needs. We can offer a variety of feeding, folding, stacking, and finishing configurations – from simple to complex production processes.

Key advantages:

- Customizable according to folding scheme, speed, format, and paper weight

- Solutions adaptable regardless of the number of folds or turns

- Consultation, configuration, and integration into your existing production line

- Wide selection of suppliers and technological solutions

Contact us, and we will help you find the best solution for your application.

Collating, folding, and stapling equipment

- Automatically collate and precisely stitch sheets into a complete publication;

- Fold printed products into accurate booklets or brochures;

- Ensure strong and aesthetically pleasing staple binding (with options for flat or saddle-stitch spine);

- Efficiently handle both digital and offset print.

- Producing catalogues, brochures, and magazines;

- Binding educational materials and notebooks;

- Preparing marketing publications – from short promotional booklets to thick prospectuses.

DUPLO ISADDLE 5.0 Saddle Stitch System

Fully automatic Duplo iSaddle 5.0 – Saddle Stitching System. The main market distinction of this line is its saddle-stitching mechanism. The system can be configured with either collating towers or a dual-tray digital sheet feeder.

Technical specifications:

- Minimum sheet size: 120 × 210 mm

- Maximum sheet size: 356 × 610 mm

- Paper weight: 64–300 g/m²

- Booklet thickness: up to 6 mm

- Speed: up to 5,000 booklets/hour

- Speed for 2-up booklets: up to 10,000 booklets/hour

Applications:

- Brochure saddle-stitching

- Notebook stitching

Duplo DBM-700i Booklet System

Fully Automatic Duplo Booklet System 700i – Collating and Stitching Line.

The line consists of one or two DC-10/60i collating towers, the DBM-700 stitching and folding unit, DBM-700T front trimmer, DKT-200 side trimmer, and a long delivery conveyor for finished products.

Technical specifications:

- Minimum paper size: 105 × 148.5 mm or 120 × 170 mm

- Maximum paper size: 350 × 508 mm or 230 × 610 mm

- Paper weight: 50–300 g/m²

- Maximum booklet thickness: up to 6 mm

- Production speed: up to 5,200 booklets/hour

DUPLO DBM-150

Duplo DBM-150 is an automatic booklet making system that performs three key functions: stapling, folding, and front trimming. Before stapling, the paper set is automatically jogged and aligned to minimize the risk of inaccurate stapling. At the end of the process, the folded and stapled booklet is front-trimmed for a professional finish.

Main advantages:

- Automatic jogging and alignment before stapling – ensures greater accuracy

- Integrated process: stapling, folding, and front trimming in one pass

- Manual or automatic paper feeding

- User-friendly LCD control panel – format change without mechanical adjustments

Technical specifications:

- Paper weight: 64–300 g/m²

- Minimum paper size: 120 × 210 mm

- Maximum paper size: 320 × 460 mm

- Maximum stapling thickness: 25 sheets or 2.5 mm

- Minimum booklet size: 120 × 80 mm

- Maximum booklet size: 320 × 230 mm

- Production speed: up to 2,400 booklets/hour

DUPLO DBM-350

Duplo DBM-350 – Professional Booklet Making and Folding System. The Duplo DBM-350 is a professional booklet making and folding system designed for medium-volume production. This module combines high speed, precision, and flexibility, making it ideal for both digital and offset print environments. It features quiet operation, a compact design, and intuitive touchscreen control for efficient and user-friendly operation.

Main advantages:

- Automatic size and stapling position adjustment – quick job changeovers

- Compatible with DSF-2200, DSF-6000, DBS-350, and DBM-350T modules

- Modular construction – easily expandable to meet production needs

- Compact footprint – saves valuable floor space

- Quiet operation – comfortable use in any workspace

Technical specifications:

- Maximum paper size: up to 320 × 460 mm

- Minimum paper size: 120 × 210 mm

- Paper weight: 64–300 gsm

- Stapling types: flat or loop staples

- Maximum booklet thickness: up to 2.5 mm

- Production speed: up to 3,000 booklets/hour

Other equipment

- Exceptional cutting accuracy – clean edges even when working with delicate or thick materials;

- Robust aluminum construction – long-lasting durability, even under intensive use;

- Versatility – capable of cutting paper, cardboard, plastics, PVC, foam boards, textiles, and more;

- Safety – built-in guards and ergonomic design ensure comfortable and secure operation.

- Advertising agencies;

- Printing houses;

- Photo laboratories;

- Other facilities where precise and high-quality manual cutting is required.