Prepress equipment

Libra Vitalis » Products » Equipment » Prepress equipment

Spectrophotometers

- Ci60 / Ci62 / Ci64 – Compact, portable spectrophotometers for everyday color inspection on a variety of surfaces – from plastics to painted components. Ideal for production environments where speed, accuracy, and mobility are essential.

- Ci4x00 Series (e.g., Ci4200, Ci4400) – Stationary, laboratory-grade spectrophotometers designed for more precise color measurement and analysis. Commonly used in quality control departments, color formulation, and standards compliance testing.

- Ci7XXX Series (e.g., Ci7600, Ci7800) – High-end spectrophotometers delivering extremely accurate measurements in accordance with international standards. Designed for advanced quality control in industries such as pharmaceuticals, cosmetics, automotive, and more.

- CiF3200 – A spherical spectrophotometer with UV processing capability, intended for textiles, plastic films, and paper. Enables evaluation of fluorescence, surface texture, gloss, and the effects of lighting on color.

eXact 2

X-Rite eXact 2 – A handheld spectrophotometer designed for precise colour measurement in the printing and packaging industries. This device ensures the highest colour accuracy, fast operation, and intuitive handling under production conditions. It is the second-generation model of the “eXact” series, significantly improved compared to its predecessor.

- Measurement Modes: Supports M0, M1, M2, and M3 lighting standards simultaneously, allowing highly accurate evaluation of various materials, including optically brightened substrates and fluorescent inks.

- Measurement Geometry: 45°/0° optical configuration ensures precise and repeatable results across different surfaces.

- Mantis™ Camera: Integrated video viewfinder allows the operator to precisely align the measurement spot in real-time. Especially useful for small colour areas or bar-scale regions.

- Touchscreen: Large, colour touchscreen with an intuitive user interface enables easy operation of all functions with minimal steps.

- Print Quality Control: Measures density, color distribution, dot gain, gray balance, trapping, and other control parameters according to G7, ISO, PSO, or Japan Colour standards.

- Spot Colour Verification: With the integrated Pantone library and Pantone LIVE support, quickly verify and compare colours against standards and use the “Best Match” feature for optimal colour approximation in production.

- Scan Mode: Allows rapid measurement of color strips or scale lines using the device wheel, automatically detecting measured areas.

- Fast Measurement: Next-generation sensors and processors deliver results within seconds.

- Accuracy Calibration: Built-in automatic calibration ensures consistent results without frequent manual maintenance.

- Wireless Connectivity: Wi-Fi and Bluetooth support allow integration into company networks or colour management systems without cables.

- Software Integration: Fully compatible with ColorCert, NetProfiler, InkFormulation, and other colour quality management systems.

eXact

X-Rite eXact – A handheld spectrophotometer designed for color measurement in the printing and packaging industries. This device ensures reliable and accurate color measurement, fully compatible with major industry standards. It is a trusted and widely used tool for print quality control in offset, flexographic, and digital printing.

- Measurement Modes: Supports M0, M1, and M2 light sources, allowing colors to be evaluated according to different standards and accounting for fluorescent optical brighteners.

- Measurement Geometry: 45°/0° geometry ensures precise color measurement while eliminating the influence of gloss on results.

- Modular Options: Available in several configurations (densitometer, basic spectrophotometer, advanced with additional functions), enabling adaptation to different user needs.

- Color Library: Built-in Pantone library allows quick comparison of printed colors against standards.

- Print Quality Control: Measures optical density, dot gain, trapping, balance, neutrality, and other print quality parameters. Particularly suitable for supporting G7, ISO 12647, and PSO workflows.

- Color Matching: The “BestMatch” feature evaluates how close a selected color is to the target and suggests adjustments by modifying ink concentrations.

- Spot Color Verification: Allows storage of company or client standard spot colors in internal memory for quick comparison during production.

- Fast Measurement: Measurements are performed instantly, providing immediate results, including Lab*, ΔE, density, and other parameters.

- Calibration: Integrated white calibration ceramic tile enables fast and accurate device calibration anywhere in the workspace.

- USB Connectivity: Data transfer to a computer via USB, compatible with Color iQC, InkFormulation, and other color management systems.

i1 Basic PRO 3

X-Rite i1 Basic Pro 3 – A handheld spectrally-based measurement device designed for professional color calibration and profiling in digital printing, photography, design, and color management. This is the third-generation i1 Pro model, significantly improved in terms of accuracy, speed, and measurement stability. It is used for calibrating monitors, projectors, and performing reflective and emissive measurements.

- Spectral Measurement: 380–730 nm range with 10 nm optical steps provides precise evaluation of color composition on both light-emitting and reflective surfaces.

- Dual Functionality: Measures both reflected and emitted (radiant) light, making it suitable for both screen and print profiling.

- High-Precision Optics: Enhanced optical system and more sensitive sensors ensure greater measurement accuracy, better repeatability, and reduced environmental sensitivity.

- Monitor Calibration: Creates ICC profiles for standard and wide-gamut displays, including HDR and 4K screens.

- Projector Calibration: Includes a projector adapter for calibrating projected images in meeting rooms or cinemas.

- Print Device Profiling: Measurement data can be used with additional hardware or software for profiling scanners, printers, or flatbed devices.

- Color Verification: When used with ColorChecker targets, enables checking and comparing colors across various surfaces, evaluating ΔE and other parameters.

- i1Profiler Display Version (included): Used for calibrating screens, projectors, and creating ICC profiles.

- Supports Advanced Workflows: Compatible with Adobe® software, RIP systems, ColorChecker, Fiery Color Profiler, Capture One, and more.

- Upgradeable to i1 Publish Pro 3: The same device can be expanded via software for print profiling and print quality control.

- Measurement Geometry: 45°/0° for reflective measurements, integrated illumination for displays

- Spectral Range: 380–730 nm

- Optical Step: 10 nm

- Measurement Modes: Reflectance, Emittance

- Connectivity: USB-C (with adapter)

- Calibration: Integrated white-point calibration tile

i1 Publish PRO 3

X-Rite i1 Publish Pro 3 – The most advanced version of the i1 Pro series, designed for professional color profiling across all workflows – from monitors to print. This device enables the creation of highly accurate ICC profiles for displays, projectors, scanners, RGB and CMYK printers, and allows monitoring of color quality in print according to international standards. It is a comprehensive solution including all necessary hardware and software for a complete calibration and color management workflow.

- Universal Calibration System: One device covers all color management workflows: displays, print, projectors, scanners, and more.

- Full i1Profiler Software: The included i1Profiler software allows creation of ICC profiles for all devices, quality analysis, and metamerism evaluation.

- Color Accuracy Control: Comprehensive color control functionality – including ΔE calculations, neutrality analysis, G7 support, and print standard comparisons.

- Print Profiling: Creates precise ICC profiles for CMYK, CMYK+, and even 7+ color printing systems using advanced target creation strategies.

- Display Calibration: Calibrates and profiles single or multiple monitors, including wide gamut, HDR, and 4K displays.

- Scanner Profiling: Using ColorChecker targets, creates scanner profiles for both reflective and transmissive measurements.

- Projector Calibration: Includes an adapter for calibrating and profiling projectors in work or presentation spaces.

- Measurement Geometry: 45°/0°

- Spectral Range: 380–730 nm

- Optical Step: 10 nm

- Measurement Types: Reflectance, Emittance

- Measurement Modes: Manual, Scan

- Connectivity: USB-C

- Software: i1Profiler Publish version, ColorChecker Camera Calibration

i1 Basic PRO 3 PLUS

X-Rite i1 Basic Pro 3 Plus – An advanced version of the i1 Pro 3, specially designed for calibration and profiling of large-format, textile, and non-standard materials. This model features a larger measurement aperture and additional functions required for precise color management on unconventional, textured, or very large media.

- Larger Measurement Aperture: 8 mm aperture optics provide more stable results when measuring coarse, textile, textured, or uneven surfaces.

- Wider Measurement Area: Ideal for large-format prints, textiles, canvas, vinyl, photo paper, and other non-standard substrates.

- Enhanced Optics: High-sensitivity sensors deliver accurate results even with low reflectance levels or fluorescent inks.

- Large-Format Printing: Profiles printers working with banners, tents, canvas, or other non-standard media.

- Textile Industry: Color calibration on fabrics, both natural and synthetic – suitable for direct-to-garment (DTG) printing and sublimation printing.

- Extensive Display Support: Calibrates professional wide-gamut displays, including HDR monitors and projectors.

- Emittance Measurement: Measures both light-emitting sources (screens) and reflective surfaces (printed media), as in the base model.

- Measurement Geometry: 45°/0°

- Aperture: 8 mm

- Spectral Range: 380–730 nm

- Optical Step: 10 nm

- Measurement Types: Reflectance, Emittance

- Connectivity: USB-C

- Measurement Modes: Manual, Scan (with extended target support)

- Software: i1Profiler (Display license)

i1 Publish PRO 3 PLUS

X-Rite i1 Publish Pro 3 Plus – A top-tier spectrophotometer for professional color profiling and quality control, specially designed for large-format printing, textiles, packaging, and complex materials. This is an advanced version of the i1 Publish Pro 3, featuring a larger measurement aperture, improved accuracy on textured surfaces, and the ability to work with non-standard media – from fabrics to vinyl and canvas.

- Larger 8 mm Aperture: Enables precise measurements on uneven, porous, or textile surfaces where standard spectrophotometers may not provide stable results.

- Extended Target Measurement: Comes with a longer scanning controller suitable for larger measurement targets typical in wide-format and textile printing.

- Advanced Profiling: With full i1Profiler software, ICC profiles can be created for CMYK, CMYK+, DeviceLink, and RGB printers, as well as displays, projectors, and scanners.

- Large-Format Print Profiling: Ideal for profiling banners, tents, UV panels, adhesive films, and other materials commonly used in advertising displays or POS production.

- Textile Printing: Accurate color profiling for fabrics used in DTG (direct-to-garment), sublimation, or pigment dyeing processes.

- Packaging Industry: Profiles complex substrates such as metallized films, transparent plastics, and corrugated cardboard.

- Comprehensive Color Management: Calibrates displays, projectors, and scanners while measuring both reflectance and emittance in a single device.

- Measurement Geometry: 45°/0°

- Spectral Range: 380–730 nm

- Optical Step: 10 nm

- Measurement Types: Reflectance, Emittance (displays, projectors)

- Aperture: 8 mm

- Connectivity: USB-C

- Measurement Modes: Manual, Scan (with extended track)

- Software: i1Profiler Publish, ColorChecker Camera Calibration

i1iO

X-Rite i1iO – An automated measurement stand designed for use with i1 Pro 3 and i1 Pro 3 Plus spectrophotometers. This device transforms manual color target measurement into a fully automated process, ensuring greater accuracy, repeatability, and speed. It is ideal for users who need to regularly and efficiently measure large volumes of color charts.

- Automated Target Measurement: With the push of a button, the device moves the measurement head across the entire target automatically, without human intervention.

- Compatibility with i1 Pro Series: Works with i1 Pro 3 and i1 Pro 3 Plus models, and supports previous i1 Pro generations.

- Thick Substrate Support: Can measure materials up to 10 mm thick, such as textiles, canvas, or plastics.

- Reflective and Transmissive Measurements: With i1 Pro 3 Plus, the device can measure both reflectance and light transmission through transparent or semi-transparent materials.

- Print Profiling: Automates the creation of CMYK, CMYK+, and RGB profiles by measuring high-density color charts.

- Textile and Large-Format Printing: Ideal for large or non-standard surfaces requiring stable contact with the measurement head.

- Packaging Solutions: Suitable for metallized, plastic-coated, or transparent materials commonly used in the packaging industry.

- Quality Control: Consistently monitors print stability during production.

- Compatibility: i1 Pro 3, i1 Pro 3 Plus, previous i1 Pro generations

- Measurement Surface Size: Up to A3+ (depending on version)

- Substrate Thickness: Up to 10 mm

- Positioning Accuracy: ±0.05 mm

- Measurement Modes: Reflectance (standard), Transmittance (with i1 Pro 3 Plus)

- Control: Via software (USB connection)

- Calibration: Automatic through i1 Pro spectrophotometer system

- Power Supply: External AC power source

Colour Management Systems

- Objectively evaluate colour accuracy and compliance with standards.

- Ensure production consistency across different materials and printing devices.

- Create ICC profiles for printers, monitors, projectors, and scanners.

- Automate colour control, reducing the risk of human error.

- Save time and materials by achieving the correct colour the first time.

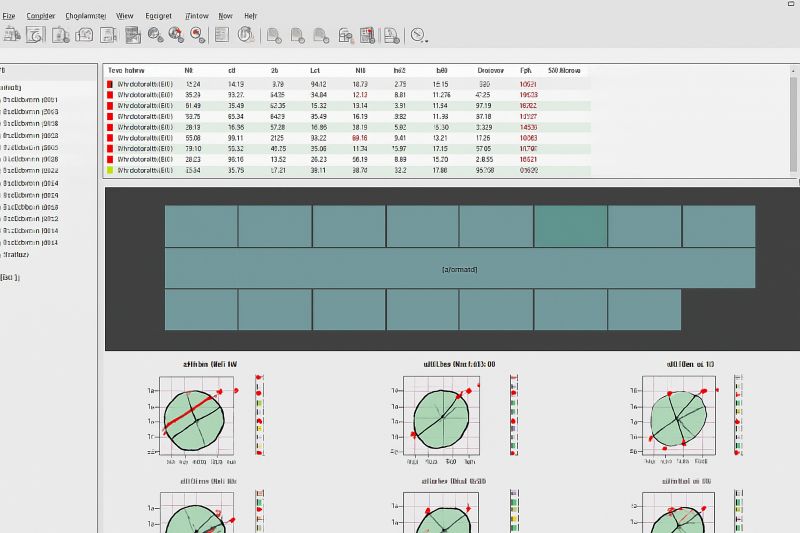

IntelliTrax2

IntelliTrax2 – an advanced automated color control system designed for sheetfed printing. It quickly and accurately scans color control strips directly from freshly printed sheets and transmits the data to a color management system or directly to the press controller.

- Instant Scanning: The entire control strip spectrum is scanned in under 10 seconds – no manual input or positioning required.

- Automatic Recognition: The system automatically detects sheet position, control strip type, color patches, and their location.

- Direct Press Integration: Correction suggestions can be automatically sent to the press, allowing operators to respond immediately to color deviations.

- Supports Various Press Configurations: Works with CMYK, CMYK+ (5–8 colors), varnished or metallic strips, and complex combinations.

- Comprehensive Measurements: Measures densitometric, spectrophotometric, tonal, and optical parameters simultaneously.

- Sheetfed Offset Printing: Ideal for rapid verification of color compliance against reference standards.

- High-Volume Production: Perfect for factories aiming to reduce waste, optimize make-ready times, and ensure color accuracy.

- Brand Color Consistency: Helps maintain precise color across different production units, print days, or presses.

- Reading Speed: ~10 seconds per sheet

- Measurement Geometry: 45°/0°, based on ISO 13655

- Supported Formats: From B3 to B1 (and larger)

- Measurement Modes: Densitometric, Spectrophotometric, M0, M1, M2

- Connectivity: Ethernet, USB, integration with color management systems

- Calibration: Automatic, integrated

Software

- Ensure Colour Accuracy: The software enables measurement and correction of colour deviations, creation of precise ICC profiles, and ensures visual consistency across different materials, devices, or production sites.

- Automate Processes: Many solutions automate tasks that were previously performed manually, reducing the likelihood of errors, saving time, and allowing faster production startup.

- Manage Colour Recipes: Certain programs are designed for creating ink mixtures, optimizing pigment usage, minimizing waste, and ensuring repeatable colour accuracy.

- Centralize Quality Control: The software allows real-time monitoring of compliance with colour standards, recording of measurement data, and analysis of results in centralized reports.

- First-Time Colour Accuracy: Achieve better compliance with client colour specifications or brand guidelines on the first attempt.

- Reduced Costs: More efficient use of materials, fewer trial runs, and less waste.

- Increased Productivity: Faster production startup, shorter make-ready times, and clearer process control.

- Traceability: Collected data enables monitoring of production quality, identification of trends, and documentation of compliance with quality standards.

Autura

X-Rite Autura – An advanced cloud-based platform for color management, standard compliance, and centralized quality control across the printing and packaging production chain. It is professional software designed for creating, adjusting, and optimizing ink formulations. Autura is intended for printers, ink manufacturers, and mixers aiming to produce the exact required color with minimal material usage and maximum repeatability.

- Cloud-Based System: Access from anywhere without complex local installations, always using the latest version.

- Centralized Color Database: A single location for color standards, libraries, tolerances, approved colors, and their statuses.

- Digital Color Approval System: Colors can be approved remotely based on objective measurements, without sending physical samples.

- Integration with Quality Control Equipment: Works with spectrophotometers, scanners, and other measurement devices, allowing centralized data collection and analysis.

- Direct Production Integration: Printers can see in real time which colors are approved, their tolerance parameters, and monitor compliance during production.

- Packaging Production: Both brand owners and suppliers can coordinate color accuracy across multiple printers or even different countries.

- Brand Color Management: Ensures consistent application of color requirements across all production sites.

- Print Supply Chain Coordination: All participants – from designers to manufacturers – access the same color data and use the same version.

- Color Quality Documentation: Every approval or rejection is recorded with measurements, date, and user information.

- Platform: Cloud-based, browser-accessible

- Supported Formats: CxF, PDF, TIFF, LAB, spectral data

- Integration: X-Rite spectrophotometers, ink formulation systems, third-party MIS

- Account Management: User groups, permissions, activity tracking

- Compatibility: PC/Mac, mobile devices via browser

Ink Formulation

X-Rite InkFormulation – Professional software for creating, adjusting, and optimizing ink formulations. It is designed for printers, ink manufacturers, and mixers who aim to produce the exact required color with minimal material usage and maximum repeatability.

- Color Recipe Generation: The system automatically calculates the optimal pigment mixture to achieve the desired color with precise spectrophotometric data.

- Color Correction: Quickly adjust an existing formula if the initial mix does not match the desired result.

- Use of Remaining Ink: The software allows inclusion of leftover inks from inventory into new formulations, reducing waste and costs.

- Material Library: Centralized database of inks, pigments, varnishes, and other components, including optical properties, density, and base type (water-based, UV, solvent-based, etc.).

- Repeatability: Created recipes can be saved, documented, and reused in the future without additional trial processes.

- Printers: Used on-site to mix the required color before production, considering the substrate, ink base, and printing type.

- Ink Suppliers: Create precise formulations according to ordered colors and ensure repeatability across different production batches.

- Packaging Production: Essential for ensuring accurate brand color compliance on different materials.

- Platform: Windows OS

- Languages: Multilingual environment, including international standards

- Compatibility: Works with X-Rite spectrophotometers (e.g., eXact, i1 Pro, Ci6x, etc.)

- Supported Ink Types: Solvent-based, water-based, UV, varnishes, specialty inks

- Color Spaces: LAB, LCH, XYZ, spectral data, ΔE2000, etc.

- Data Export: PDF reports, color formula files, integration with MIS/ERP systems

Color IQC

X-Rite Color iQC – Advanced color quality control software designed to ensure accurate and consistent color compliance across all production stages. It enables real-time measurement, analysis, and documentation of color data, helping suppliers, printers, and brand owners maintain quality according to precise standards.

- Color Matching Evaluation: Compares production results with targets using ΔE and other colorimetric criteria.

- Workflow Automation: Tools for color approval, analysis reports, alerts, and automatic compliance calculations.

- Spectral Analysis: Utilizes full spectral data for precise color assessment, ensuring high accuracy.

- Flexible Tolerance Settings: Allows different criteria for different colors, projects, or clients.

- Data Storage and Traceability: Every measurement, match, or deviation is documented and can be included in reports.

- Printers and Ink Manufacturers: Monitor and verify that production achieves the ordered color, recording all measurement results.

- Supply Chain Management: Ensures supplier-produced colors meet brand requirements, regardless of geographic location.

- Brand Owners: Use for quality monitoring and maintaining color standards across multiple production sites.

- Laboratories: Conduct precise color analysis according to client-provided standards or internal criteria.

- Platform: Windows OS, local or network installation

- Supported Formats: LAB, LCH, XYZ, spectral data, CxF, PDF

- Reports: Automated PDF reports, color comparison charts, user notifications

- Compatibility: Works with all major X-Rite devices and third-party measurement instruments

- Data Security: User access management, database archiving, traceability based on measurement history

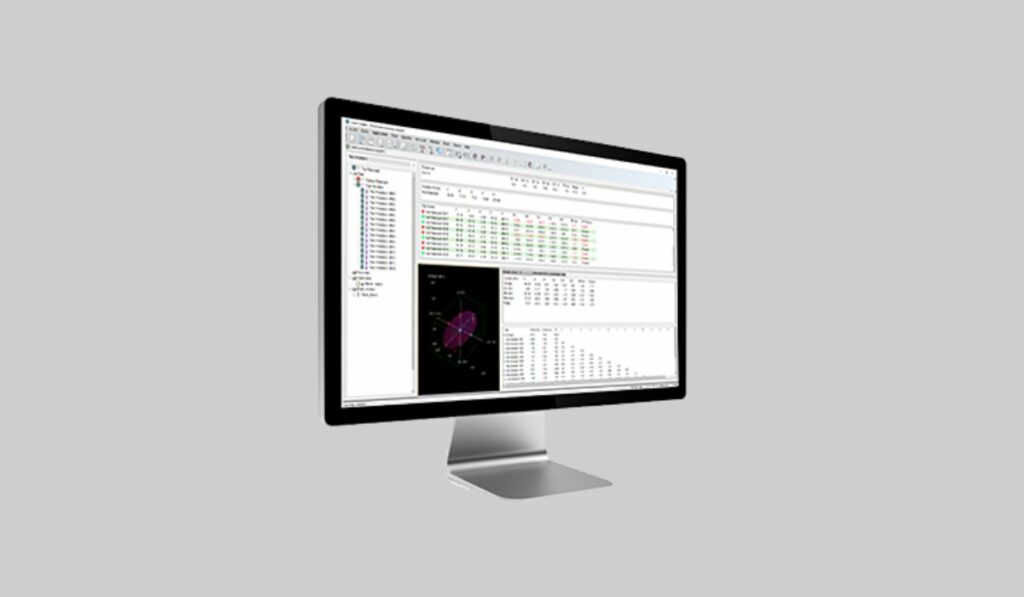

ColorCert

X-Rite ColorCert – An advanced color quality management platform designed to monitor, evaluate, and standardize print processes in real time from start to finish. This system connects all participants in the print supply chain – from brand owners to printers – enabling collaboration on the same color targets and criteria.

- Real-Time Quality Management: Measurement data from the pressroom is transmitted to a centralized system, allowing color accuracy monitoring during production.

- Color Data Consolidation: All quality measurements, color tolerance data, and production parameters are collected in a single, analyzable space.

- Standardized Evaluation Criteria: Enables consistent use of tolerance and assessment methods across all production sites.

- Automated Reports and Certificates: Generates quality compliance reports, color match scorecards, and certificates according to specific client requirements.

- Press Integration: Works with spectrophotometers and inline/nearline measurement devices directly in the press process.

- Printers: Use ColorCert to measure and adjust color compliance in real time, reduce waste, and achieve production stability faster.

- Brand Owners: Access production statistics to ensure consistent color standards are maintained across all production sites.

- Supply Chain Control: Helps monitor whether different suppliers adhere to specified color requirements and achieve the desired quality level.

- Platform: Windows-based, cloud-supported

- Components: ColorCert Desktop Tools, ColorCert Scorecard Server, ColorCert Repository Server

- Data Formats: Spectral data, CxF, PDF, ΔE2000, Scorecard formats

- Integration: X-Rite spectrophotometers (e.g., IntelliTrax2, eXact), print management systems (MIS/ERP), ink formulation systems

- User Management: Centralized user access and permission control

Color iMatch

X-Rite Color iMatch – Advanced color formulation and optimization software designed specifically for textiles, plastics, paints, and other industries requiring precise color. It uses spectral analysis algorithms to quickly calculate pigment, dye, or ink combinations that ensure accurate color matching with minimal physical trials.

- Accurate Color Formulation: Calculates the optimal combination of ingredients to achieve the desired color result.

- Fast Color Matching: Spectral analysis and advanced algorithms significantly reduce the number of physical trials and adjustments required.

- Virtual Formula Preview: Simulates color appearance on different materials, lighting conditions, and surface treatments.

- Use of Remaining Materials: Incorporates existing pigment or ink stocks to optimize material usage and reduce waste.

- Library Management: Creates and maintains pigment and formula libraries, enabling rapid creation of repeatable or similar shades.

- Textile Industry: Generates precise color formulations for different fabric fibers and processing methods.

- Plastics Manufacturing: Calculates color mixes considering polymer properties, transparency, and surface texture.

- Paint and Coating Production: Ideal for developing formulas for paints, varnishes, and coating systems where accurate color match and stability are critical.

- Suppliers and Manufacturers: Ensures repeatable color solutions across different production sites or batches.

- Platform: Windows OS

- Interface: User-friendly, configurable environment with a clear workflow

- Data Formats: Supports spectral files, recipe export, and report generation

- Color Models: LAB, LCH, spectral data, ΔE94, ΔE2000, and more

- Supported Ink/Pigment Types: Liquid, powder, plastic pigments, textile dyes

GMG ColorProof

GMG ColorProof – a world-class professional software solution designed to ensure color accuracy and consistency during the prepress process.

- “Plug & Proof” System: Comes with pre-installed printing standard profiles for minimal setup complexity.

- GMG ProofStandard / CalibrationSet: Ensures compliance with printing norms and prevents errors in proofs.

- GMG ProofControl Inline Module: Automated proof verification using data from integrated measuring devices.

- Adobe PDF Print Engine 2.5 Integration: Guarantees identical color reproduction as Adobe RIP solutions.

- WebClient and Remote Proofing: Centralized management of proofing across multiple locations via browser or FTP.

- Universal Spot Color Support: Supports PANTONE, CxF/X-4, and other spot color systems – precise rendering via GMG OpenColor integration.

- Integrated Dot/RIP System: Handles both 1-bit (DotProof) and continuous tone (ContoneProof) graphics.

- Proofing according to ISO, GRACol, PSO, SWOP, and other international standards.

- Packaging, labeling, and brand publishing where accurate logos, design, colors, and halftones are critical.

- International or multi-site proofing workflows requiring consistent color control across locations.

- Platform: Microsoft Windows

- Device Compatibility: Works with various Proof Control Strip measurement devices, including integrated printers and i1 spectrophotometers.

- Integration Protocols: Supports FTP, WebClient, IO-Link, USB, and Ethernet.

GMG OpenColor

GMG OpenColor – an advanced color profiling system designed for packaging printing, where additional colors, diverse substrates, and complex ink combinations are often used. This software enables highly accurate prediction and control of color reproduction even under challenging printing conditions.

- Spectral Color Modeling: The system analyzes spectral data to calculate how inks will behave on specific paper or other substrates.

- N-Dimensional Profiles: Creates color profiles covering any ink combination (CMYK, spot colors, and their mixtures).

- Accurate Overprint Simulation: Ensures that even layered colors are rendered correctly, avoiding unexpected visual deviations.

- Fast and Efficient Workflow: Minimal measurement data is required to generate a new profile.

- Automatic Profile Updates: Quickly adapts to changes in printing conditions or substrate materials.

- Packaging printing with spot colors, metallic finishes, or non-standard substrates.

- Printing houses requiring precise color control throughout all production stages.

- Design and brand management, ensuring consistent color accuracy from design creation to final print.

- Profiling Types: Proofing and separation profiles

- Supported Ink Channels: 4 to 12 inks per profile

- Data Type: Spectral

- Integration: Compatible with GMG proofing and color management systems

- Interface: Intuitive GUI with profile preview, correction, and analysis capabilities

- Platform: Windows, network-enabled

GMG ColorServer solution Bundles

GMG ColorServer – an automated color conversion platform designed to consistently process and adapt print data for different media, printing processes, and ink sets. GMG offers three specialized solution packages – Digital, Conventional, and Multicolor – each optimized for specific use cases.

- GMG ColorServer Digital: tailored for digital printing (CMYK), e.g., large-format, advertising, or packaging printing, where fast reproduction and repeatability are critical.

- GMG ColorServer Conventional: focused on traditional printing (offset, flexo, gravure), fully compliant with industry standards (e.g., PSO or GRACol) and supports spot color integration.

- GMG ColorServer Multicolor: designed for printing with more than 4 colors: CMYK plus spot or extended spot colors, particularly relevant for packaging.

- Automated Color Management and Conversion: Transforms data into the desired color space according to preset protocols.

- GMG MX Technology: High-quality color conversion ensuring accuracy and consistency.

- InkOptimizer and SmartProfiler: Digital workflow tools for ink savings and controlling press costs.

- Seamless Integration: All versions support GMG OpenColor for managing spot color trends.

- Digital Printing & Packaging: Fast adaptation to client requirements with consistent repeatable results.

- Conventional Printing: Ensures strict adherence to standards while optimizing production time and costs.

- Multicolor Printing: Integrates additional spot colors and achieves high color accuracy in packaging.

- Supported Color Profiles: GMG MX, ICC, OpenColor Multicolor

- File Formats: PDF/X, TIFF, JPEG, PSD, EPS, AI

- Color Conversion: Automated using DeviceLink technology

- Profile Management: Centralized, with SmartProfiler and OpenColor integration

- With GMG ColorProof: proofing

- With GMG ColorPlugin: Photoshop/Illustrator

- With MIS, RIP, and workflow systems: Esko, HYBRID, EFI, etc.

- Platform: Windows Server 64-bit

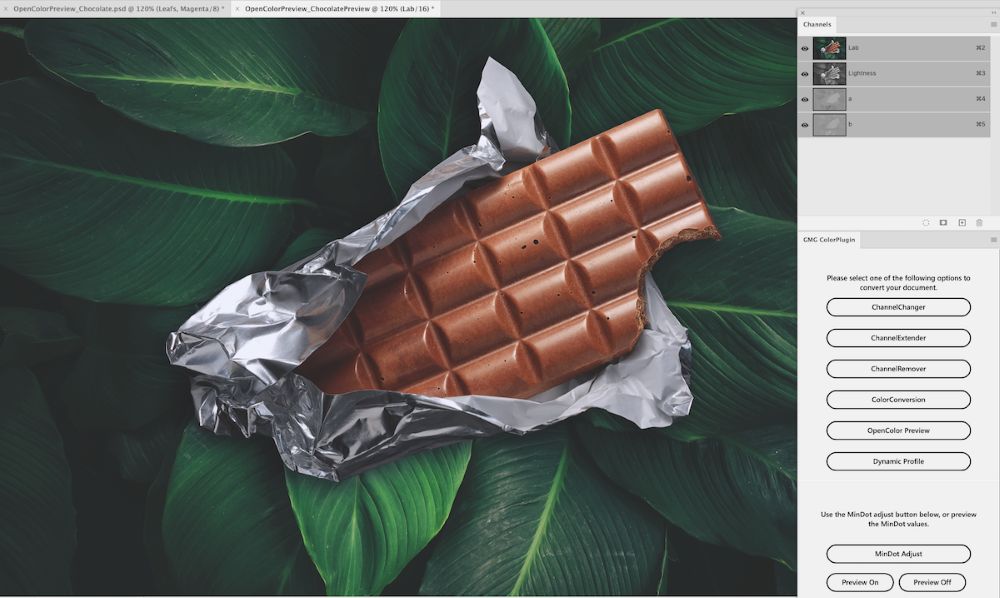

GMG ColorPlugin

GMG ColorPlugin – a professional plugin designed for designers and print specialists to perform color conversions, channel adjustments, spot color additions, and previews directly within Adobe Photoshop or Illustrator. This tool saves time and significantly simplifies complex operations.

- RGB → Multicolor Separation: Supports up to 7 colors based on GMG OpenColor profiles – ideal for advanced packaging printing.

- ChannelExtender, ChannelChanger, ChannelRemover: Add, modify, or remove individual color channels, with automatic compensation to ensure color stability.

- ColorBoost: Enhances color vibrancy and saturation without loss of quality.

- MinDot Preview and MinDot Adjust: Optimizes fine details and reduces the risk of printing artifacts in spot color layers.

- Soft Proofing: Provides accurate on-screen visualization of the final output.

- Ideal for packaging designers and printing houses working with spot colors or multichannel printing.

- Suitable for both high-level graphic editing and fast, repeatable production jobs – supports full images as well as individual layers/elements.

- Integrates seamlessly into advanced prepress workflows, enabling precise color tasks to be executed quickly within Photoshop/Illustrator without additional systems.

- Compatibility: Adobe Photoshop and Illustrator (latest versions)

- Licensing: Managed via GMG Manage user account (Standard, Pro, Packaging versions)

- Operating Environment: Windows or macOS, with integrated GMG OpenColor support

GMG ColorCard

GMG ColorCard – an advanced digital system designed for the rapid and highly accurate creation of printed spot color samples (ink drawdowns).

- Fully Digital Ink Drawdown Process: Color references are printed directly from .CxF files.

- Wide Substrate Support: Simulates colors on different papers and boards.

- Speed: Color samples are produced within minutes, with consistent and repeatable results.

- Flexible Layout Configuration: Allows inclusion of tints, tolerance indicators, or custom client data in layouts.

- Easy Repeatability: Color cards can be printed at any time; digital data is stored for immediate replication.

- Brand Color Communication: Provides reliable color references for all stakeholders.

- Ink Laboratories and Print Shops: Efficiently validate spot colors without costly and lengthy trial runs.

- Packaging Design and Production Control: Minimizes unpredictable printing results and shortens the approval cycle.

- Color Rendering Method: Digital ink drawdown based on spectral analysis

- File Support: .CxF color specifications

- Preparation Time: ~3 minutes per color

- Color Consistency: Identical reproduction every time

- Layout Tools: Various layouts supporting tints, tolerances, and client-specific data

- Operating Environment: Compatible with GMG ColorProof and supports Epson Spectro printers

CTP solutions

- Extremely precise image generation – up to 5 µm drum accuracy

- Automatic plate feeding, imaging, and punching

- Compatible with UV and thermal plate technologies

- Supports various formats – from B3 to B0 and newspaper sizes

- Remote management via the “LaBoo” system

- H+ Series – high-end thermal CTP systems for professional commercial printing

- G+ Series – versatile UV CTP solutions combining performance with broad plate compatibility

- TP Series – dedicated newspaper CTP systems, extremely fast and efficient

- DD870/880 – dual-drum CTP systems for maximum productivity