Post-press equipment

Libra Vitalis » Products » Equipment » Post-press equipment » Post-press equipment: calendar making, foiling

Digital Embellishment Machines

- Luxury packaging finishes – cosmetics, beverages, perfumes, and technology products;

- Premium printed materials – catalogues, brochures, covers, and gift vouchers;

- Business and special occasion prints – invitations, postcards, gift cards, and restaurant menus;

- Brand enhancement – highlighting logos and key design elements with varnish or metallic foil.

- Fast and precise processing for both small and medium print runs;

- No need for expensive dies or lengthy setup;

- Ability to apply custom effects with millimetre precision.

- Embossed (3D) varnish;

- Gloss or matte coating;

- Gold, silver, or coloured foil.

SCODIX ULTRA 6500

Scodix Ultra 6500 – a professional digital varnishing and foiling solution designed for high-quality B1 format print finishing. The system enables the creation of stunning 3D effects by enhancing printed materials with multiple layers of polymer and various foil applications.

Key advantages:

- Resolution up to 2540 × 450 dpi

- Automatic positioning with ±100 µm precision

- Up to 7 layers of raised polymer

- Productivity up to 1,310 sheets/hour

- Supports both hot and cold foiling

- Compatible with offset, HP Indigo, inkjet, and other printing technologies

- Compact footprint with pallet-based feeding

Technical specifications:

- Maximum sheet size – 760 × 1060 mm

- Printable area – 700 × 1000 mm

- Substrate thickness – up to 2 mm

- Substrate weight – 135–675 gsm

DUPLO DuSense DDC-810PRO

Duplo DuSense DDC-810 PRO – an advanced digital spot varnishing system designed for precise and high-quality print enhancement. Its compact design, automated operation, and fast job setup make it an ideal solution for print providers looking to add premium finishing effects to their products.

Key advantages:

- CCD camera with automatic registration

- Variable data support and automatic job switching

- Fiery JobFlow for fast and efficient job preparation

- Adjustable coating thickness from 15 µm to 80 µm

- Compact footprint – ideal for limited spaces

- Compatible with both digital and offset prints, including laminated surfaces

Technical specifications:

- Print format: from 210 × 279 mm to 364 × 750 mm

- Maximum print area: 322.5 × 736.5 mm

- Coating thickness: 15–80 µm (adjustable in 5 µm steps)

- Speed: up to 60 A4 sheets/min

DUPLO DuSense DDC-8000

Duplo DDC-8000 – a partial B2 format UV coating system designed for varnishing various paper types and surfaces, including coated, uncoated, and laminated sheets. The machine features an integrated in-line foiling module, allowing both processes to be performed simultaneously.

Technical specifications:

- Minimum sheet size: 279 × 279 mm

- Maximum sheet size: 585 × 1068 mm

- Paper weight: 160–600 gsm

- Speed: up to 1,500 sheets/hour

- Coating thickness: 10–80 µm

Applications:

- Business cards

- Calendars

- Postcards

- Packaging

- Leaflets

- Menus

Calendar making equipment

- Reliable automated solutions;

- Suitable for products of various formats and thicknesses;

- Fast operation and precise perforation without errors.

- Semi-automatic and fully automatic systems;

- Fast changeover between formats and wire sizes;

- Adaptable to different production volumes.

Die-cutting and foiling equipment

- Contour cutting for products of various shapes;

- Foiling with glossy, matte, or embossed foil – no printing dies required;

- Suitable for small to medium print runs.

- Quick job setup – no complex preparation required;

- Compact design – convenient for use in various print shop spaces;

- Simple and intuitive operation.

SCS DCH60

SCS Automaberg DCH60 – an automatic flatbed cutting machine designed for cutting paper and cardboard. The step-cutting feature saves both setup time and die production costs. The machine can be equipped with a hot foiling function.

Functionality:

- Cutting

- Hot foiling

- Braille embossing

- Embossing

- Kiss-cut

Technical specifications:

- Maximum cutting size: 350 × 500 mm

- Maximum sheet size (single step): 550 × 380 mm

- Maximum sheet size (multiple steps): 550 × 710 mm

- Minimum sheet size: 220 × 220 mm

- Paper thickness: 120 g/m² to 4 mm

- Cutting force: 60 T (600,000 N)

SCS DCH200

Flatbed automatic cutting machine designed for cutting paper and cardboard. The step-cutting feature saves setup time and die production costs. The machine also includes an automatic waste removal system.

Main functions:

- Cutting

- Braille embossing

- Embossing (relief stamping)

- Kiss-cutting

Technical specifications:

- Maximum cutting size: 490 × 700 mm

- Maximum sheet size: 540 × 1000 mm

- Minimum sheet size: 300 × 300 mm

- Material thickness: 150 g/m² to 2 mm

- Corrugated cardboard: up to 4 mm

- Cutting force: 200 T (2 MN)

DUPLO DSM-1000

Duplo DSM-1000 – a versatile automatic machine designed for precise and rapid cutting, creasing, perforating, or foiling of various print products. It is ideal for digital, offset, or hybrid printing, and its fast job setup allows efficient processing of both small and medium print runs.

Key advantages:

- High-precision cutting, creasing, perforating, and kiss-cutting in a single cycle

- Fast job setup – die changes in just a few minutes

- Intuitive touchscreen control with job parameter saving

- Accurate sheet feeding with vacuum feeder and air separation

- Capable of handling various materials up to 600 g/m²

- Optional waste separation system and registration mark reader

Technical specifications:

- Paper size: 279 × 279 mm to 530 × 750 mm (B2)

- Paper weight: up to 600 g/m²

- Maximum operating speed: up to 3,100 sheets/hour

- Pressing force: up to 40 tons

- Feeding capacity: up to 400 mm

Paper guillotines

- Models with various cutting widths – 520 mm, 670 mm, 920 mm, 1150 mm, 1300 mm, 1370 mm;

- Adaptable to production volume and format requirements.

- High precision – clean and straight cuts, even on complex projects;

- User-friendly operation – intuitive interface and programmable settings;

- Robust construction – durability and stability for intensive use;

- Various width models – adaptable to specific printing requirements;

- Safety systems – protection for both the operator and the work process.

Roll-fed label finishing equipment

- Gemini Star, Gemini E-line, Jet D-Screen models;

- Hot stamping, embossing, and digital varnishing;

- High-quality finishing with professional results.

- WX I, WX II, NX 8, SF4 models;

- Automatic contour cutting without dies;

- Flexible for quick job changes;

- Suitable for small and medium print runs.

CARTES Gemini Star

Cartes Gemini Star – a versatile and compact roll label finishing line designed for professional finishing of digitally printed self-adhesive labels. Its modular design allows the machine to be configured according to specific needs, combining functions such as varnishing, hot foiling, embossing, and laser cutting.

Key advantages:

- Modular structure – flexible configuration

- JET D-Screen embossing and doming effects

- ILC (Invisible Laser Cutting) – cutting without white contours

- Hot foiling, UV coating, laminating, perforation

- Preset storage and intuitive operation

- Compact and energy-efficient solution

Technical specifications:

- Maximum material width – 360 mm

- Maximum roll diameter – up to 600 mm (up to 800 mm optional)

- Speed – up to 140 m/min (physical finishing), up to 700 m/min (laser cutting)

- Digital embossing – up to 800 µm, resolution up to 1440 dpi

- Pressing force (for foiling) – up to 60 kN

CARTES Jet D-Screen

Cartes Jet D-Screen – an advanced digital decoration technology designed for producing high-value labels. This system enables embossed UV varnishing, metallic surface effects (doming), hot foil simulation, and Braille embossing – all without dies, cost-effectively and with high precision.

Key advantages:

- Digital embossed UV varnishing without dies or printing plates

- Ability to create cold foil effects – shiny metallic decoration without heat

- Thick varnish application – embossing up to 800 µm

- Braille printing with certified accuracy

- Drop-on-Demand technology with high resolution up to 1440 dpi

- Intuitive operation and job parameter storage

Technical specifications:

- Maximum varnishing width: up to 350 mm

- Embossing thickness: up to 800 µm

- Printing resolution: 360–1440 dpi

- Varnishing technology: Drop-on-Demand (DoD) UV ink

- Foiling: cold foil with LED UV curing

- Maximum speed: up to 25 m/min (depending on embossing thickness)

- Integration: operates as a module in the Cartes GEMINI line or as a standalone station

CARTES Gemini E-line

Cartes GEMINI E-Line is a new-generation fully electric label finishing system designed for maximum precision, efficiency, and sustainability. This modular equipment is intended for roll-to-roll self-adhesive label finishing, combining technologies such as digital embossing, cold foiling, hot stamping, die-cutting, and laser cutting.

Main advantages:

- Fully electric drive – no pneumatics or hydraulics, lower energy consumption, and easier maintenance

- Integrated Cartes JET D-SCREEN system – digital embossing, foiling, Braille

- Laser cutting with ILC (Invisible Laser Cutting) technology – exceptionally clean and precise cuts even on dark materials

- Simple modular architecture – ability to choose and combine required finishing functions

- Intuitive operation via a large touch screen with comprehensive process monitoring

- Top-level production quality without compromise – suitable for both small and medium print runs

Technical specifications:

- Working material width: up to 360 mm

- Maximum roll diameter: up to 600 mm (optionally up to 800 mm)

- Varnishing speed: up to 50 m/min (depending on coating thickness)

- Embossing height: up to 800 microns

- Printing resolution (JET D-SCREEN): up to 1440 dpi

- Laser cutting speed: up to 700 m/min

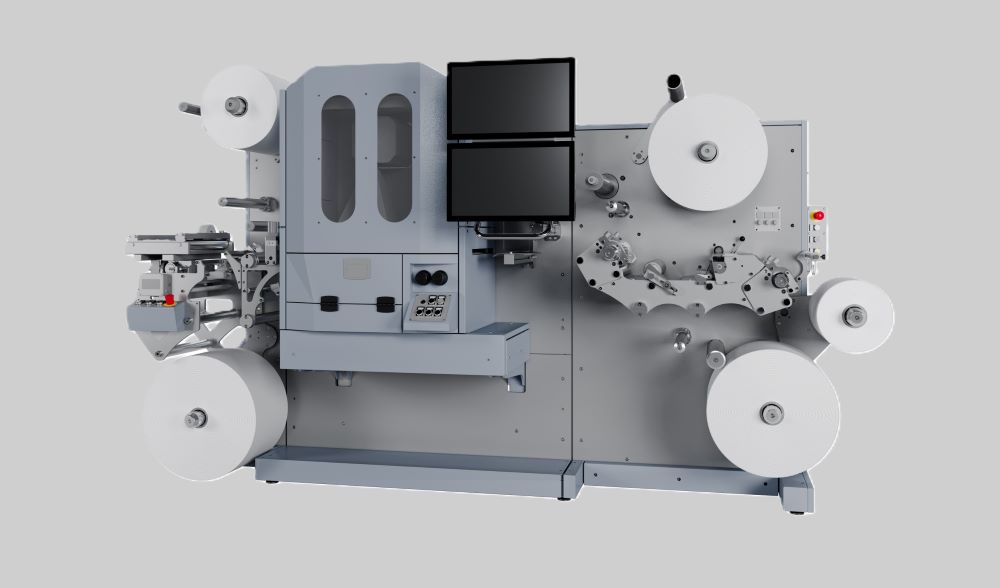

VALLOY Duoblade WX I

Roll-to-roll digital label cutting machine with four kiss-cut cutting heads. An integrated camera allows users to cut multiple jobs (cutting files) simultaneously without stopping the machine.

Automatic cutting head positioning optimizes the cutting trajectory and maximizes productivity. The machine also features cold laminating capability.

An integrated web guide system ensures precise and straight material feeding.

Key technical specifications:

- Speed – up to 9 m/min

- Roll diameter – up to 450 mm

- Roll width – 100–350 mm

- Maximum label size – 350 × 600 mm

- Number of cutting heads – 4

- Cutting tolerance – ±0.2 mm

- CCD camera for code reading

- Roll-to-sheet option

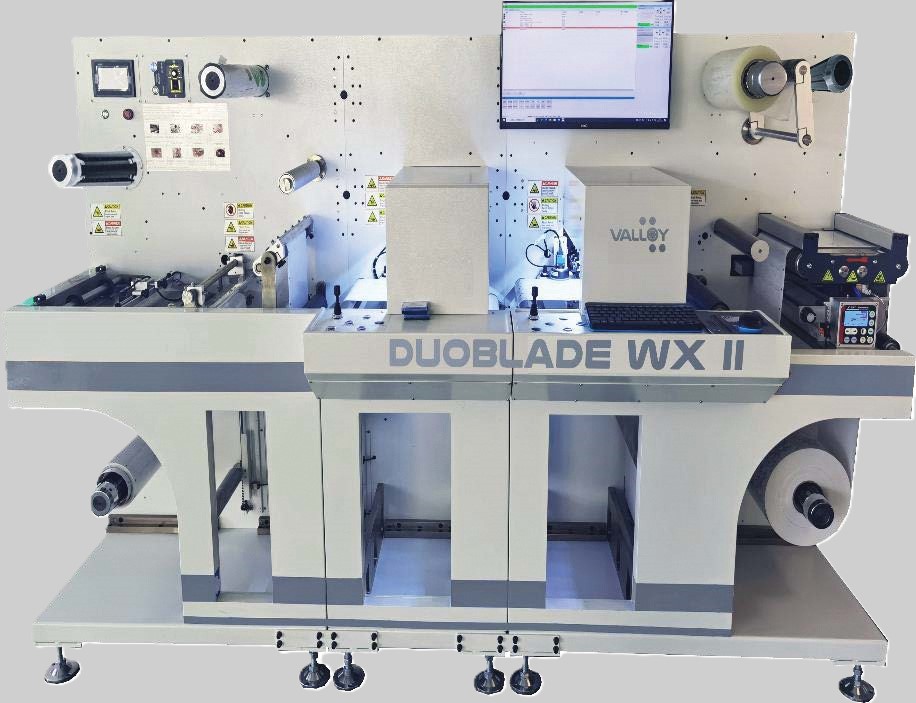

VALLOY Duoblade WX II

Roll-to-roll digital label cutting machine

The machine features four kiss-cut cutting heads. An integrated camera allows multiple jobs (cutting files) to be processed simultaneously without stopping the machine. Automatic cutting head positioning optimizes the cutting path and maximizes productivity.

Key technical specifications:

- Maximum roll width: 350 mm

- Maximum cut object length: 600 mm

- Operating speed: up to 9 m/min

- Maximum roll diameter: 450 mm

VALLOY Duoblade NX 8

Valloy Duoblade NX 8 – an advanced digital roll label finishing system designed for efficient and precise production of small and medium print runs. This machine stands out with eight cutting heads, automatic blade control, and smart workflow management, significantly reducing manual intervention and accelerating production.

Key advantages:

- 8 independent cutting heads – increased productivity and flexible die options

- Automatic cutting depth adjustment – precise operation when changing materials without manual intervention

- CCD camera with QR/barcode recognition – automatic job switching without stopping the machine

- Integrated functions: laminating, contour cutting, kiss-cutting, and waste removal

- Intuitive touchscreen interface – quick setting adjustments and workflow management

- Compact design – saves space and adapts to various production environments

Technical specifications:

- Number of cutting heads: 8

- Maximum material width: up to 350 mm

- Maximum roll diameter: up to 450 mm

- Cutting speed: up to 12 m/min

- Accuracy: ±0.1 mm

- Control: touchscreen interface with automatic format recognition

- Additional functions: laminating, kiss-cutting, waste removal, automatic feeding

VALLOY Duoblade SF4

Valloy Duoblade SF4 – an advanced digital roll label finishing system designed specifically for single units and small print runs where fast job changeovers and high precision are essential. Its compact design allows complex elements to be produced from a single roll – cutting, creasing, or perforating in one pass.

Key advantages:

- 4 tools in operation – enables cutting, creasing, perforating, or kiss-cutting in a single pass

- CCD camera with registration mark recognition and automatic barcode-based job selection – fast job changeover without operator intervention

- Automatic format adjustment and robotic job setup

- Ideal for digital printing – perfect for effects on packaging, labels, invitations, all in a single process

Technical specifications:

- Number of tools: 4 independent tools (cutting, creasing, perforating)

- Cutting speed: up to 12 m/min

- Accuracy: ±0.1 mm

- Control: intuitive touchscreen, CCD registration system, automated barcode recognition

Cutters, Creasers, Folders, Perforators

- Models: DC-446, DC-618, DC-648, DC-F100;

- Automated processing with high precision;

- Fast job changeover – for flexibility and efficiency.

- High-quality creasing, even on thicker paper;

- Professional finishing with fast job setup.

DUPLO DC-446

Duplo DC-446 – an automatic creasing machine designed to eliminate manual work and improve accuracy. Simple operation via the control panel allows for quick paper parameter setup, while the machine handles the rest of the process automatically.

Key advantages:

- Vacuum belt feeding prevents slipping or damage to the paper

- Ultrasonic double-sheet detection ensures precise feeding

- Up to 100 mm high feeding tray reduces the need for frequent reloads

- Ability to create up to 20 creases with 0.1 mm accuracy and choose from three crease widths

- Optional perforation or trimming modules – two operations in a single pass

Technical specifications:

- Paper weight: 110–350 g/m²

- Minimum size: 140 × 150 mm

- Maximum size: 330 × 670 mm

- Speed: up to 60 sheets/min

- Program memory: up to 30 different settings

Applications:

- Postcards, invitations, tickets

- Book covers, brochures, leaflets

- Menus, promotional booklets, and more

DUPLO DC-618

Duplo DC-618 – a multifunctional finishing machine designed to perform three key post-press processes: trimming to final size, creasing, and perforating.

An integrated CCD camera reads printed barcodes on the printed sheets, automatically selecting the appropriate cutting, creasing, and perforating parameters. Changing the machine’s operating settings requires no mechanical adjustments – all parameters can be modified via the control panel or through specialized software on a computer.

The Duplo DC-618 minimizes the risk of misalignment during trimming, as each sheet is individually scanned based on printed registration marks. Its patented vacuum belt feeding system prevents slippage and protects the print during feeding. An integrated ultrasonic system eliminates the risk of multiple sheets being fed at once.

Key technical specifications:

- Paper weight: 110–400 g/m²

- Minimum paper size: 210 × 210 mm

- Maximum paper size: 330 × 750 mm (up to 1000 mm with optional extension)

- Maximum speed: 23 sheets/min

- Minimum finished size: 48 × 50 mm

- Tolerance: ±0.3 mm

Applications:

- Business cards

- Postcards

- Invitations

- Photos

- Book covers

- Brochures

- Menus

- Leaflets

- Tickets

- Promotional booklets

DUPLO DC-648

Multifunctional trimming, creasing, and perforating machine

A multifunctional machine designed to perform three key finishing processes: trimming to final size, creasing, and perforating. It is fully integrated with Xerox/EFI Fiery print servers, eliminating the need for any additional operator intervention.

Technical specifications:

- Minimum paper size: 210 × 210 mm

- Maximum paper size: 370 × 1200 mm

- Paper weight: 110–400 g/m²

- Speed: up to 40 sheets/min

- Minimum finished size: 48 × 49 mm

Applications:

- Business cards

- Invitations

- Covers

- Postcards

- Promotional print materials and more

DUPLO DC-F100

Duplo DC-F100 – a compact yet powerful in-line folding system designed for integration with DC-618/DC-648 slitter–cutter–creaser machines. It is ideal for print shops looking to automate creasing, perforating, and trimming after digital or offset cutting in a single process – from sheet to finished folded application.

Key advantages:

- Fully automated folding: V, C, Z, double-parallel, gate, and closed gate formats

- Dual knives and spring-loaded rollers automatically adjust to paper thickness (110–400 g/m²)

- CCD camera with barcode and registration mark recognition

- Wider format support: 50–1000 mm length, minimum 48 mm width, trimming up to 1000 mm

Technical specifications:

- Paper weight: 110–400 g/m² (double-parallel: 110–230 g/m²)

- Minimum width: 48 mm

- Stacker capacity: top – 400 mm, bottom – 100 mm

- Optional integration with DC-618 card stacker

Multigraf CF375

Multigraf CF-375

The Multigraf CF-375 performs two functions simultaneously – creasing and folding. It can handle up to two folds in a single pass. Optional perforation wheels are available to expand the machine’s capabilities.

Technical specifications:

- Minimum paper size: 105 × 148 mm

- Maximum paper size: 375 × 660 mm

- Paper weight: 100–400 g/m²

- Speed: up to 5,000 sheets/hour

- Feed table loading height: up to 100 mm