Post-press equipment

Libra Vitalis » Products » Equipment » Post-press equipment

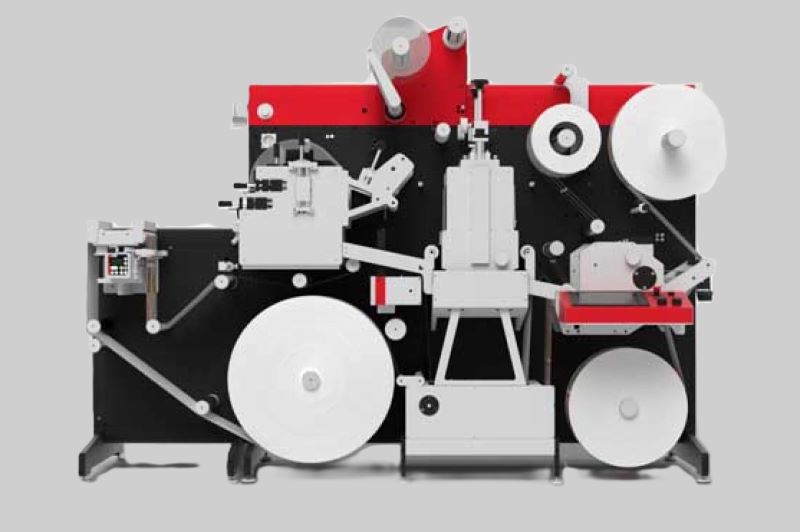

Laminating equipment

High-quality laminating machines are designed for efficient coating of printed sheets with glossy, matte, or special protective films. The range includes compact, easy-to-use models such as IGEPA MASTERSEAL Pro and Tecnomac Easy, as well as advanced, high-performance solutions like Tecnomac Evolution and Tecnomac Sprinter. All machines feature precise working temperature control, fast warm-up times, and user-friendly operation, making them ideal for both smaller print shops and professional production lines.

IGEPA MASTERSEAL Pro

IGEPA MASTERSEAL Pro – roll laminator with easy operation and a heated top roller.

- Maximum sheet width: 1620 mm

- Maximum material thickness: 23 mm

- Maximum speed: up to 6 m/min

- Maximum temperature: +60 °C

- Indoor printing

- Outdoor printing

TECNOMAC Easy

Tecnomac Easy – a dependable automatic laminator designed for both digital and offset printing. Featuring user-friendly operation, fast warm-up, and high-quality lamination, it is ideal for small to medium print runs.

- Automatic paper feeding and separation

- Pneumatic pressure roller for even lamination

- Compatible with all types of thermal films (glossy, matte, soft touch)

- Compact design – perfect for workspaces with limited space

- Maximum sheet width: 52 cm

- Paper weight: 115–350 g/m²

- Operating speed: up to 10 m/min

TECNOMAC Evolution

Tecnomac Evolution – a state-of-the-art industrial laminator designed for medium to high-volume production. Built to ensure flawless lamination quality even under intensive use, this model is ideal for professional print shops and manufacturers who value performance, precision, and versatility.

- Fully automatic operation – from feeding to discharge

- Integrated sheet separator with efficient sheet separation

- Precise temperature and pressure control

- Compatible with all types of thermal films (BOPP, PET, soft touch, etc.)

- Ergonomic control panel with touchscreen

- Maximum sheet width: 76 cm

- Paper weight: 115–600 g/m²

- Operating speed: up to 30 m/min

TECNOMAC Sprinter

Tecnomac Sprinter – a premium semi-automatic laminator designed for professional applications in both digital and offset printing. This model stands out for its fast warm-up, reliable performance, and flexibility when working with a variety of laminating films. It is an excellent solution for print shops seeking a balance of quality and efficiency.

- Semi-automatic operation – manual feeding with automatic sheet separation

- Pneumatic pressure system ensures consistent lamination results

- Quick machine setup

- Compatible with various thermal films (matte, gloss, soft touch, metallic, etc.)

- Maximum sheet width: 52 cm

- Paper weight: 130–350 g/m²

- Operating speed: up to 15 m/min

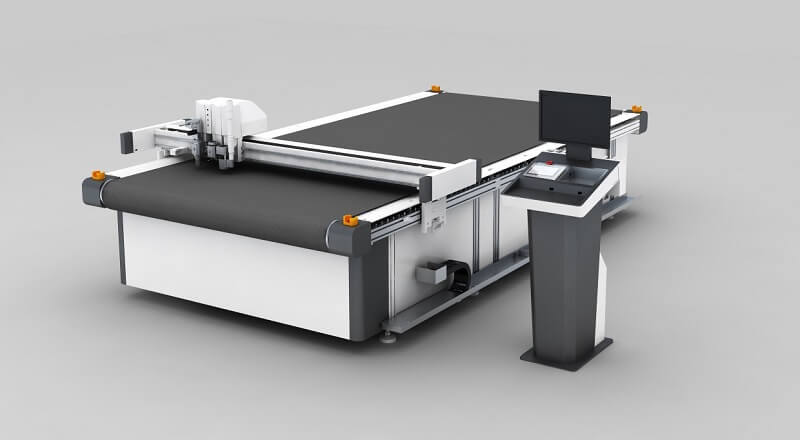

Flatbed cutters

- Work with a wide range of materials – from paper and adhesive film to PVC, cardboard, rubber, and even leather;

- Cut complex contours and small detail elements with precision and clean edges;

- Automate the process, reducing production time and minimising the need for manual labour.

- Producing boxes from corrugated cardboard;

- Cutting promotional materials – POS stands, posters, stickers, and signs;

- Creating models and prototypes – quickly and accurately;

- Processing print products in non-standard shapes;

- Cutting labels, tents, films, plastics, and other specialised materials.

ELITRON KOMBO SD 31.20+

Working areas and tools:

- Working area: 1600 × 2000 mm or 3100 × 2000 mm

- Electric and pneumatic oscillating knives

- 1 kW or 3 kW milling modules

- Kiss-cut, creasing, V-cut, and rotary knives

Automation and features:

- Automatic 40-zone vacuum system

- Seeker System with camera for job recognition

- Automatic tool height detection and change

- Monolithic (solid) table

Technical specifications:

- Speed – up to 102 m/min

- Working height: 20, 50, or 120 mm

- Milling speed – up to 60,000 rpm

- Vacuum pump – 7.5 kW, 40 zones

- Dimensions: 2850 × 2400 mm or 4270 × 3250 mm

- Weight: 2100 or 2600 kg

ELITRON KOMBO SDC 31.20+

Working area:

- 3100 × 2000 mm

Configuration:

- The Elitron cutter comes equipped with a variety of working tools: electric oscillating knife, pneumatic oscillating knife, 1 kW or 3 kW milling modules, kiss-cut, creasing wheels, V-cut, and rotary knives.

Functions and advantages:

- Automatic 40-zone vacuum system

- Design system

- Seeker System with an additional camera for automatic job recognition and file selection

- Automatic height adjustment for cutting and milling tools

- Automatic milling tool change

- Monolithic (solid) table

- Automatic feeding and unloading system for roll materials

Key technical specifications:

- Working area: 3100 × 2000 mm

- Speed – up to 102 m/min

- Working height: 20, 50, or 120 mm

- Milling tool rotation speed – up to 60,000 rpm

- Vacuum pump – 7.5 kW, 40 working zones

- Dimensions – 4700 × 3120 mm

- Weight – 2900 kg

ELITRON KOMBO SDC 31.32+

The multifunctional Elitron flatbed cutter with conveyor belt is a versatile solution for a wide range of industries and applications: outdoor advertising, digital printing, corrugated cardboard, aluminum composite and PVC printing and cutting, milling of various plastics and wood, sign production, leather and textile processing, and more.

Key technical specifications:

- Working area – 3100 × 3200 mm

- Maximum material thickness – 50 mm

- Speed – up to 102 m/min

- 36 vacuum zones

ELITRON KOMBO TH

The multifunctional Italian-made Elitron flatbed cutter features two cutting heads that operate simultaneously. This solution allows for up to double the productivity.

Key technical specifications:

- Working area – 3150 × 2050 mm

- Maximum material thickness – 50 mm

- Speed – up to 102 m/min

- 40 vacuum zones

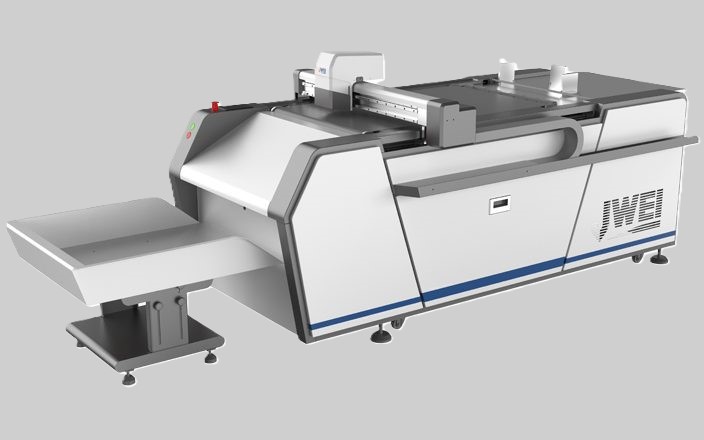

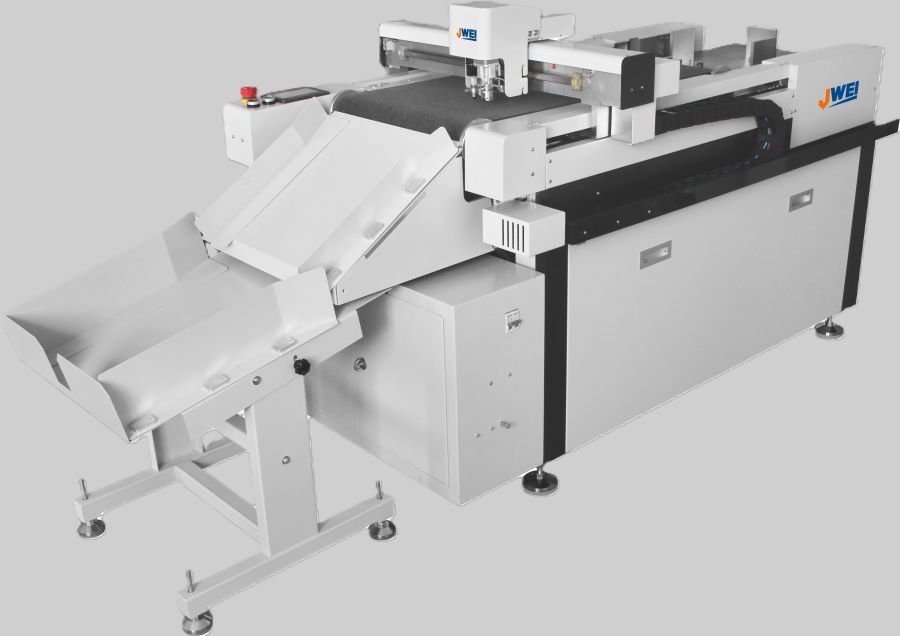

JWEI CB03II-2516

Entry-level automatic flatbed cutter with conveyor belt, capable of using up to two different tools simultaneously.

Available tools and functions:

- Oscillating knife

- Tangential knife

- Kiss-cut

- Creasing

- Milling

- Textile cutting

- V-cut

The conveyor belt ensures automatic and uninterrupted feeding and cutting of roll materials. The machine can also be equipped with an automatic sheet material feeding system.

For textile cutting, the machine is equipped with a specialized camera.

Technological features:

- Robust aluminum frame

- Camera for registration mark reading

- Automatic tool height adjustment

- Vacuum table divided into six zones

- Servo motors for X and Y axis movement

Key technical specifications:

- Working table size – 3100 × 2100 mm

- Cutting speed – up to 1200 mm/s

- Cutting height – up to 50 mm

- Accuracy – ±0.1 mm

- Acceleration – 1G

JWEI CB08II-3121

Automatic flatbed cutter with conveyor belt, capable of using up to two different tools simultaneously.

Available tools and functions:

- Oscillating knife

- Tangential knife

- Kiss-cut

- Creasing

- Milling

- Textile cutting

- V-cut

The conveyor belt ensures automatic and uninterrupted feeding and cutting of roll materials. The machine can also be equipped with an automatic sheet material feeding system.

For textile cutting, the machine is equipped with a specialized camera.

Technological features:

- Robust aluminum frame

- Rack-and-pinion system ensuring cutting precision

- Camera for registration mark reading

- Automatic tool height adjustment

- Vacuum table divided into six zones

- Servo motors for X and Y axis movement

Key technical specifications:

- Working table size – 3100 × 2100 mm

- Cutting speed – up to 1200 mm/s

- Cutting height – up to 50 mm

- Accuracy – ±0.05 mm

- Acceleration – 1G

- Power – 18 kW

- Dimensions – 3970 × 2997 × 1450 mm

JWEI LST03II-0806

JWEI LST03II-0806 is a professional, compact digital cutter designed for processing sheet materials such as cardboard, stickers, synthetic papers, or thin plastic films. This model is ideal for small to medium-scale production – box prototypes, custom orders, POS materials, and finishing print jobs.

Key advantages:

- Automatic sheet feeding and collection – efficient operation without constant operator intervention

- CCD camera and QR code recognition – automatic file selection and precise cutting registration

- Suitable for cutting, creasing, perforating, and marking – with interchangeable tools

- No traditional dies required – cutting directly from digital files

- Perfect choice for print shops producing single items or small batches

Technical specifications:

- Working area – 800 × 600 mm (compatible with B2 and A1 sheets)

- Maximum material thickness – up to 6 mm

- Cutting speed – up to 1200 mm/s

JWEI LST-0604

JWEI LST-0604 is a highly compact and versatile digital flatbed cutter designed for small-format products made from a variety of sheet materials. Thanks to its compact size and high precision, this model is ideal for advertising agencies, print shops, design studios, or product prototype development.

Key advantages:

- Compact size – fits perfectly in small production spaces or offices

- High-precision cutting, creasing, perforating, and marking

- Operates without traditional dies – files can be prepared in DXF, PLT, or PDF formats

- CCD camera and mark recognition – precise cutting according to print marks

- Extremely easy to use – with an intuitive control interface and specialized software

Technical specifications:

- Working area – 600 × 400 mm

- Maximum material thickness – up to 6 mm

- Cutting speed – up to 1000 mm/s

JWEI CB08II-1612

Flatbed digital cutter with conveyor belt featuring a 1.2 × 1.6 m working table. This is a versatile solution for a wide range of industries and applications: outdoor advertising, digital printing, corrugated cardboard, aluminum composite and PVC printing and cutting, milling of various plastics and wood, sign production, leather and textile processing, and more.

Compact design allows it to fit through standard 80 × 200 cm doors.

Key technical specifications:

- Maximum speed – up to 1500 mm/s

- Maximum cutting thickness – up to 50 mm (depending on material)

- Supports up to 8 different tools

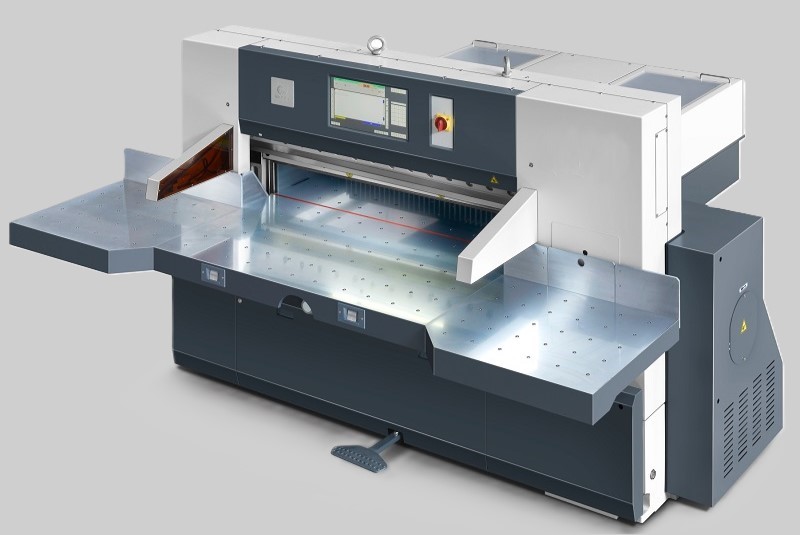

Binders

- Producing softcover books;

- Binding manuals, textbooks, and educational materials;

- Gluing catalogues, magazines, and reports;

- Processing digital print products in both small and medium print runs.

- Exceptional adhesion strength and durability;

- High flexibility of the bound spine;

- Resistance to temperature and humidity changes;

- Ideal for coated, laminated, thick, or difficult papers.

DUPLO PFI BIND 6000 PUR DUO

Automatic softcover binding machine “Duplo PFiBIND 6000 PUR”, using PUR-type adhesive. Its patented closed PUR glue system allows users to minimize adhesive consumption and simplifies equipment maintenance. Automatic cover feeding and creasing enable maximum productivity.

Technical capabilities:

- Block width up to 420 mm

- Block thickness up to 50 mm

- Minimum cover size: 140 × 260 mm

- Maximum cover size: 420 × 780 mm

- Speed: up to 600 cycles/hour

- Glue application: spine and edges

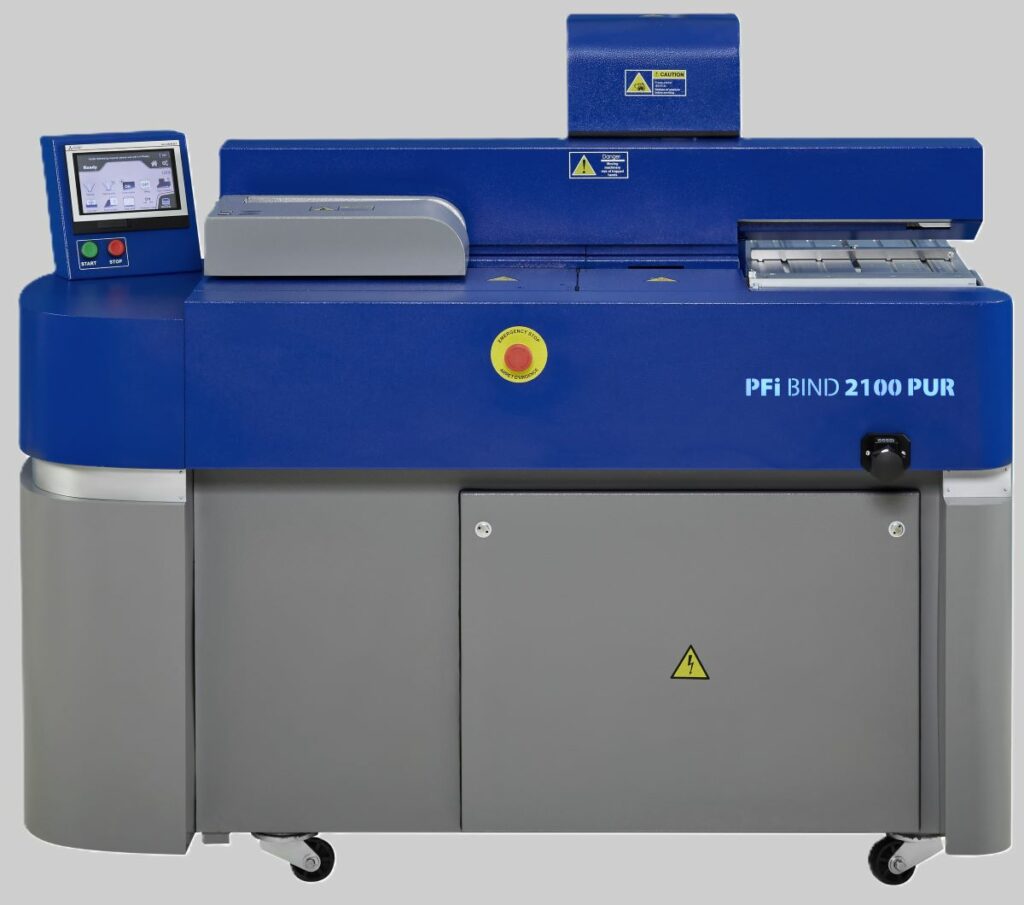

DUPLO PFi Bind 2100 PUR

Duplo PFiBIND 2100 PUR – softcover binding machine using PUR-type adhesive. These adhesives are ideal for all types of paper, including coated, offset, varnished, laminated, and more. With PUR, book blocks do not need to be stitched before binding, and the inner sheets remain strong and tear-resistant.

Technical specifications:

- Block width – up to 340 mm

- Block thickness – up to 40 mm

- Minimum cover size – 80 × 160 mm

- Maximum cover size – 340 × 900 mm

- Speed – up to 290 cycles/hour

- Glue application – spine and edges

Meccanotecnica Sirio

Meccanotecnica Sirio – advanced automatic perfect binder for small and medium print runs.

Sirio is an innovative perfect binder designed for professional softcover book production. This solution from the Italian manufacturer Meccanotecnica is ideal for small to medium print runs, and especially for single-book production on demand (Book-on-Demand).

Key advantages:

- High productivity – up to 1,350 cycles per hour

- Three independent clamps allow smooth format changes without stopping the machine

- Fully automatic machine adjustment – spine length, cover feeding, and unloading are automatically regulated

- Compatible with EVA or PUR adhesives, depending on production needs

- Integrated cover feeding system with double creasing

- Easily integrated into a complete book production line, including a trimmer (3-knife cutter)

Technical specifications:

- Working speed – up to 1,350 cycles/hour

- Recommended operating speed – approximately 1,090 books/hour

- Maximum spine length – 430 mm

- Maximum book thickness – 60 mm

Digibook Mitabind

Digibook Mitabind – fully automatic perfect binder with a single clamp, designed for high-quality softcover and hardcover book production. It is ideal for print-on-demand and small print runs where quick format changes and easy operation are essential.

Key advantages:

- Fully automatic single-clamp binding process

- Fast and easy format changes via touchscreen control

- Compact dimensions, saving production space

- Versatile operation with both softcover and hardcover books

- Integrated additional functions: spine milling, EVA hot-melt adhesive application

Technical specifications:

- Working speed – up to 300 books/hour

- Number of clamps – 1

- Book size range: width 100–320 mm, height 150–380 mm, thickness 3–60 mm

- Paper weight: 60–170 g/m² (block), cover material 100–300 g/m²

- Adhesive system: EVA Hotmelt